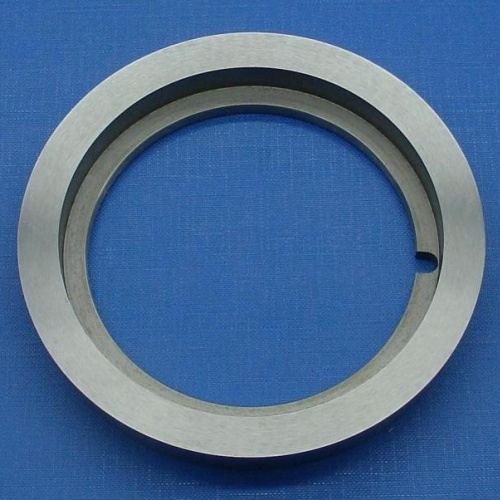

Carbide Cutting Blade

Carbide Cutting Blade Technical Specifications

|

Parameter |

Performance |

| Hardness |

HRC 85-92 (matrix), HRC 65-72 (coating) |

|

Impact Resistance |

≥40 J/cm² (ASTM E23) |

| Salt Spray Resistance |

≥1000 hours (ISO 9227), no rust or coating delamination |

|

Operating Speed |

Logging saws: 60-120 m/s; Rock crushers: 15-30 m/s |

| Temperature Range |

-50°C to 600°C (short-term peaks) |

FOTMA Industrial Cemented Carbide Blade: Custom Solutions for Extreme Applications

FOTMA tungsten carbide cutting blades are engineered for heavy-duty industrial environments like quarrying, logging, and paper mills. Built to withstand extreme wear, our custom-designed blades, circular saws, and cutters excel in crushing rocks, slicing wood, and processing fibrous materials. From massive ore fragmentation to high-speed pulp cutting, we deliver unmatched durability across industries.

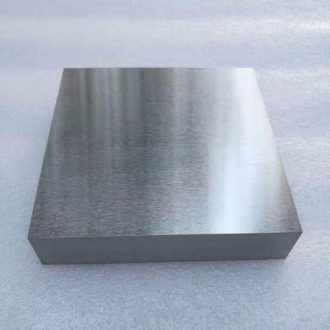

Material Advantages of Tungsten Carbide Tipped Blade

- High-Toughness Tungsten Carbide Matrix

- Ultra-Coarse Grain WC: Particle size 3-8µm with 8%-15% cobalt/nickel binder, boosting impact resistance by 200% (impact value ≥40 J/cm²).

- Cr3C2/VC Grain Inhibitors: Prevent WC grain growth under high temperatures, ensuring edge stability.

- Corrosion-Resistant Coatings

- Fatigue-Resistant Design

Density ≥14.5 g/cm³ (zero porosity), no micro-crack propagation under cyclic loads, lifespan 5-8x longer than standard blades.

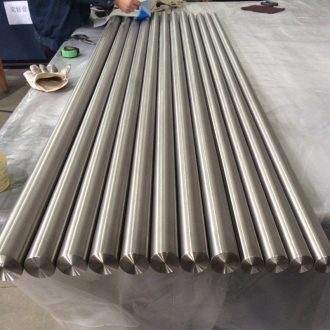

Industry-Specific Customization

| Customization | Solutions |

| Matrix Composition | ISO-standard K10/K20/K30 grades or tailored alloys (e.g., high-chromium anti-corrosion). |

| Mounting Systems | Welded bases, bolted blades, and other customized type |

| Extreme Environment | Graded materials or hybrid alloys for high-silica rock, iron-contaminated wood, or coastal corrosion. |

Technical Specifications

| Parameter | Performance |

| Hardness | HRC 85-92 (matrix), HRC 65-72 (coating) |

| Impact Resistance | ≥40 J/cm² (ASTM E23) |

| Salt Spray Resistance | ≥1000 hours (ISO 9227), no rust or coating delamination |

| Operating Speed | Logging saws: 60-120 m/s; Rock crushers: 15-30 m/s |

| Temperature Range | -50°C to 600°C (short-term peaks) |

Applications

- Quarrying: Granite/basalt crusher blades, vibrating screen liners, jaw crusher teeth.

- Logging & Wood Processing: Forestry circular saws, chipper rotors, planer blades.

- Pulp & Paper: Rotary cutters, pulper knives, metal-detection guard blades.

- Metal Recycling: Scrap shredder hammers, auto shredder blades, cable cutters.

- Cement/Mining: Clinker crusher discs, conveyor scrapers, screening system

Value-Added Services

✅ Simulation Testing: Wear resistance validation based on rock hardness/wood moisture (with video reports).

✅ Global Emergency Network: 6 spare parts hubs for 48-hour delivery (NA/EU/SE Asia).

✅ Blade Regeneration: Base remelting, laser-clad edge repair (50%-70% cost savings).

✅ Wear Mapping: On-site engineering for stepwise wear compensation designs.

Why FOTMA?

Extreme Expertise: 300+ quarries/logging clients, 1000+ material cutting database.

End-to-End Control: In-house powder metallurgy (AMS 5898 compliant), zero supply chain risks

To get latest carbide blade price, CONTACT US NOW!

LATEST RECOMMENDED

Related products

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074