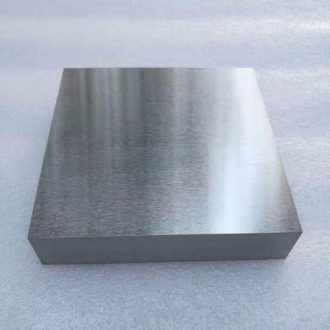

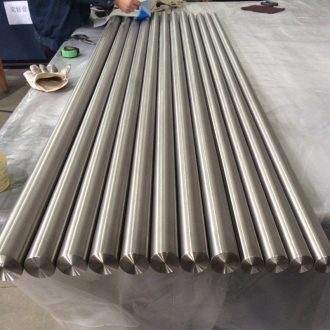

Cemented Carbide Plates

Carbide Plate Material Grade

|

Model |

WC Content | Co Content | Hardness HRA | Transverse Rupture Strength (MPa) | Applications |

| YG6A |

94% |

6% | 91.5 | 1800 |

Precision molds, corrosive environments |

| YG8 | 92% | 8% | 90.0 | 2200 |

General wear parts, stamping tools |

|

YG11 |

89% | 11% | 89.0 | 2600 | Medium-impact crushing tools |

| YG15C | 85% | 15% | 87.5 | 3200 |

High-impact mining components |

|

YG20X |

80% | 20% | 85.0 | 3500 |

High-temperature rolling, heavy-impact equipment |

FOTMA cemented carbide plates, with “top-tier hardness + extreme wear resistance” at their core, are engineered for harsh industrial environments! Whether facing intense impacts in mining machinery or high-temperature corrosion in chemical equipment, our plates serve as “steel armor” for equipment, significantly extending service life, saving downtime, maintenance, and costs!

Core Performance: Hardcore Material, Fearless Challenges

- Dual Assurance of Hardness and Wear Resistance

- Hardness Surpasses Steel: Tungsten carbide (YG series) plates achieve a hardness of HRA ≥ 89 (equivalent to HRC 75), with tungsten carbide content up to 70%-97%. Wear resistance is 150x higher than high-strength manganese steel.

- Adjustable Cobalt Content:

Low-Cobalt Formula (6%-8%): Designed for high-wear, low-impact scenarios (e.g., sand conveyor liners, nozzles).

High-Cobalt Formula (10%-15%): Enhanced toughness for high-impact applications like mining crusher hammers and jaw plates.

- Stability in Extreme Environments

- Corrosion Resistance: Outperforms stainless steel in acid/alkali/salt environments. Dedicated models for chemical equipment and marine engineering.

- High-Temperature Red Hardness: Maintains over 8% effective hardness retention at 600°C, ideal for hot roller bed liners and furnace guides.

- Anti-Adhesion Properties: Mirror finish (Ra ≤ 0.2µm) prevents material adhesion in food machinery and plastic molds.

- Flexible Structural Design

- Complete Size Range: Standard thickness 10-50mm (customizable up to 100mm), dimensions up to 1200×600mm.

- Composite Upgrades: Optional embedded plates (carbide + steel backing) or gradient transition layers to reduce installation costs and weight.

Customized Material Selection

| Industry | Typical Applications | Recommended Grade |

| Mining & Aggregates | Jaw crusher plates, vibrating screen panels, conveyor liner plates | YG15C (High-Impact Resistant) |

| Cement & Metallurgy | Ball mill liners, high-temperature kiln rails, steel rolling guides | YG20X (High-Temperature) |

| Chemical & Energy | Valve sealing blocks, pump flow components, nuclear valve wear parts | YG6A (Corrosion-Resistant + Coated) |

| Machinery Manufacturing | Stamping die inserts, shredder blade bases, automation equipment guides | YG8 (General Wear-Resistant) |

| Agriculture & Construction | Harvester blades, tunnel boring machine cutter heads, wood grinder hammers | YG11 (Balanced Toughness) |

Production Quality Assurance

✅ High-Purity Powder: Tungsten carbide purity ≥ 99.95%, SGS-certified for heavy metals (Pb/Cd).

✅ Cold Isostatic Pressing: 200-300MPa pressure ensures ≤ 0.5% density uniformity.

✅ Vacuum Sintering: Precision sintering at 1480°C, zero porosity/cracking.

✅ Post-Treatment: Optional sandblasting, electro polishing, laser quenching for surface enhancement.

To get latest quotation for cemented carbide products, CONTACT US NOW!

LATEST RECOMMENDED

Related products

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074