Hot Zone Parts

Is Titanium Alloy Stronger Than Titanium?

Multi-dimensional Performance Analysis of Titanium and Titanium Alloys: Strength, Modulus, and High and Low Temperature Performance 1. Strength and Hardness Properties of Titanium and Titanium Alloys △ Strength Index Titanium alloys are highly sought after in many fields primarily due to their exceptional strength. While the tensile strength of pure titanium ranges from 265 to 353 MPa, the strength of common titanium alloys is significantly higher, reaching 686 to 1176 MPa. Some specialized titanium alloys even reach 1764 MPa, demonstrating a specific strength comparable to many steel grades. This not only enhances the material’s load-bearing capacity but also demonstrates its exceptional durability in various engineering applications. In compression testing, titanium and titanium alloys demonstrate strength comparable to their tensile strength. For commercially pure titanium, the compressive yield strength is similar to the tensile yield strength, while titanium alloys such as Ti-6AI-4V and Ti-5AI-2.5Sn exhibit slightly higher compressive strength than their tensile strength. Furthermore, shear strength, a key material property indicator, is typically approximately 60% to 70% of tensile strength, further highlighting the high strength characteristics of titanium alloys. At room temperature and pressure, processed and annealed titanium and titanium alloys exhibit a high ultimate tensile strength, reaching 0.5 to 0.65 times the ultimate tensile strength. Under specific fatigue testing conditions, for example, annealed Ti-6AI-4V can achieve an ultimate tensile strength of 0.2 times the ultimate tensile strength in a notched state, further demonstrating its exceptional durability. △ Hardness Hardness is an important indicator of a material’s hardness. The highest purity grades of processed industrial-pure titanium have a relatively low hardness, typically less than 120 HB (Brinell hardness), while other industrial-pure titanium grades range from 200 to 295 HB. In contrast, pure titanium castings have a slightly higher hardness of 200 to 220 HB. For titanium alloys, the hardness in the annealed state is 32 to 38 HRC (Rockwell hardness), equivalent to 298 to 349 HB. Notably, the hardness of as-cast Ti-5Al-2.5Sn and Ti-6Al-4V, as well as Ti-6Al-4V castings with low interstitial inclusions, is higher than that of the annealed state. 2. Modulus and Toughness of Titanium and Titanium Alloys △ Elastic Modulus The tensile modulus of commercially pure titanium ranges from 105 to 109 GPa, while most titanium alloys reach a tensile modulus of 110 to 120 GPa in the annealed state, demonstrating high rigidity. Notably, age-hardened titanium alloys exhibit a slightly higher tensile modulus, while their compressive modulus is equal to or higher than

Comprehensive Applications of Tungsten-Copper Alloy in Aerospace and New Energy Vehicles

Tungsten-Copper Alloy (CuW80): A Core Material for Aerospace and New Energy In the new materials sector, one alloy, tungsten-copper alloy (CuW80), is attracting increasing attention from companies due to its advantages such as high-temperature resistance, strong conductivity, and corrosion resistance. With the rapid development of the aerospace, new energy vehicle, and high-end electronics industries, this material is taking center stage in the market. What is Tungsten-Copper Alloy (CuW80)? Tungsten-copper alloy is a composite material created through powder metallurgy by combining high-melting-point tungsten with highly conductive copper. CuW80 indicates a tungsten content of approximately 80% and a copper content of 20%. This ratio combines the high melting point, high hardness, and ablation resistance of tungsten with the high thermal and electrical conductivity of copper. This combination of rigidity and flexibility allows it to perform stably in a variety of extreme operating conditions. CuW80‘s Core Performance Advantages: High-Temperature Stability: It maintains structural strength above 2000°C and is widely used in high-temperature environments. Excellent electrical and thermal conductivity: Ensures outstanding performance in EDM, electrical contacts, and heat dissipation components. Oxidation and corrosion resistance: Enables long-term stable service under complex operating conditions. High strength and wear resistance: Suitable for manufacturing key components such as electrode blocks and switch contacts. These properties make CuW80 not just a material but also a strategic pillar of advanced manufacturing. Applications of CuW80 tungsten-copper alloy Aerospace: Rocket nozzle linings and ablation-resistant components for spacecraft, ensuring stable operation under extreme temperatures. New Energy Industry: Heat dissipation substrates for IGBT modules in new energy vehicles, improving the safety of electronic control systems. Electrical and electronic equipment: Significantly extends the life of arc contacts in high-voltage switches and vacuum switch contacts. Molds and precision manufacturing: EDM electrodes and mold heat dissipation structures improve processing efficiency and product quality. It can be said that CuW80 will be present in almost all of the highly prosperous industrial chains of the next decade, from aerospace to new energy to electronics and electrical. Why is CuW80 so promising? The world is ushering in a new era of new energy and aerospace: New energy vehicle sales have been climbing year after year, spurring a surge in demand for high-temperature heat-dissipating alloys; Frequent domestic large aircraft and rocket launches require a large amount of ablation-resistant materials; The electronics and chip industries are experiencing rapid iteration, and their reliance on high-performance heat-dissipating materials continues to grow. Tungsten-copper alloy (CuW80) addresses these pain points.

What are the applications of Al SiC composites?

Application of Aluminum Silicon Carbide (AlSiC) Substrates in IGBTs IGBTs, as power semiconductor devices, are widely used in new energy vehicles, white goods, rail transit, clean power generation, smart grids, and other fields. The internal structure of an IGBT module primarily consists of a chip, a ceramic copper-clad substrate, bonding wires, a baseplate, a heat sink, thermal adhesive, solder layer, silicone gel, and a plastic package. Heat dissipation in high-power IGBTs has always been a major obstacle to IGBT development. The baseplate in an IGBThttps://tungstenchina.com/product/high-silicon-aluminum-alloy-alsic/ module creates a heat conduction path, ensures thermal conductivity, and enhances the module’s mechanical properties. Baseplate materials are typically copper or aluminum-based silicon carbide (AlSiC). Today, we’ll explore the advantages of AlSiC as an IGBT baseplate. 1. Performance Characteristics of AlSiC Aluminum silicon carbide (AlSiC) is the abbreviation for aluminum-based silicon carbide particle-reinforced composite material, also known as silicon carbide aluminum or aluminum silicon carbide. Aluminum silicon carbide was initially used in radar chip substrates for US military aircraft, replacing tungsten copper. This substitution resulted in excellent heat dissipation and a 10 kg reduction in overall radar weight, which garnered significant attention. Due to its unique advantages, AlSiC’s penetration in IGBT baseplates has rapidly increased: 1) AlSiC boasts high thermal conductivity (170-200 W/mK), ten times that of typical packaging materials. This allows for the timely dissipation of heat generated by the chip, improving the reliability and stability of the entire component. 2) AlSiC is a composite material, and its thermal expansion coefficient and other properties can be adjusted by varying its composition. With a tunable thermal expansion coefficient (6.5-9.5 × 10⁻⁶/K), AlSiC’s thermal expansion coefficient is well matched to that of semiconductor chips and ceramic substrates, preventing fatigue failure. It even allows power chips to be mounted directly on AlSiC baseplates. 3) AlSiC is very light, only one-third that of copper, comparable to aluminum, yet boasts bending strength comparable to steel. This makes it superior in seismic performance, surpassing copper baseplates. 4) AlSiC has the highest specific stiffness of all electronic materials, three times that of aluminum, five times that of W-Cu and Kovar, and 25 times that of copper. Furthermore, AlSiC offers better vibration resistance than ceramics, making it a preferred material for harsh environments (such as those exposed to high vibration, such as those in the aerospace and automotive industries). 5) AlSiC can be mass-produced, but the processing technique depends on the silicon carbide content. Processing methods include electro-spark machining, diamond

What are the properties of AlSiC material?

Aluminum-based silicon carbide (AlSiC) is driving changes in new energy vehicles and aerospace with its innovative properties, boasting thermal conductivity 10 times greater than traditional alloys and 50% weight reduction. Its thermal expansion coefficient precisely matches that of chips, ensuring intact solder joints through 10,000 thermal cycles and doubling the lifespan of IGBT modules. The global automotive brake disc market is expected to exceed 404.6 billion yuan by 2031. Driven by the trend of lightweighting, this material, with a specific stiffness three times that of aluminum, is reshaping the boundaries of precision manufacturing for applications ranging from electronic packaging to satellite brackets and brake discs. Aluminum silicon carbide (AlSiC) is a high-performance material composed of an aluminum matrix reinforced with silicon carbide particles. Its unique physical and mechanical properties have led to its widespread application in electronic packaging, aerospace, and new energy vehicles. However, its high hardness and wear resistance also significantly increase its processing difficulty, requiring particular attention to process parameters and equipment selection when machining with milling machines. The following analysis focuses on both material properties and processing considerations. AlSiC boasts a thermal conductivity of 180–240 W/mK, approximately 10 times that of conventional Kovar alloys. This effectively dissipates heat and prevents thermal failure in electronic devices. Furthermore, its thermal expansion coefficient (6.5–9.5×10⁻⁶/K) can be adjusted to match that of semiconductor chips by adjusting the silicon carbide content, reducing fatigue cracking caused by thermal stress. While its density is comparable to aluminum (approximately 3.0 g/cm³), its specific stiffness (stiffness/density) is three times that of aluminum and 25 times that of copper. This makes AlSiC particularly suitable for weight-sensitive aerospace structures, such as satellite mounts and engine components. The addition of SiC particles significantly enhances the material’s hardness and wear resistance (HV ≥ 2500), enabling stable operation in high-temperature and highly corrosive environments, such as automotive brake discs and turbine blades. Its isotropic physical and mechanical properties make it less susceptible to deformation caused by uneven stress distribution after machining, making it suitable for the precision machining of complex structural parts. AlSiC‘s thermal conductivity (170240 W/mK) is 10 times that of traditional Kovar alloys, and its thermal expansion coefficient (6.59.5×10⁻⁶/K) matches chips and ceramic substrates, preventing thermal stress failure. For example, the AlSiC baseplate in an IGBT module can maintain an intact solder layer after tens of thousands of thermal cycles, significantly improving device reliability. Typical applications include IGBT heat sinks for new energy vehicles,

Analysis of the Outstanding Performance of Copper-Molybdenum-Copper (CMC) Electronic Packaging and Heat Sink Materials

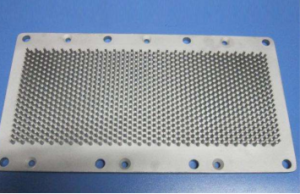

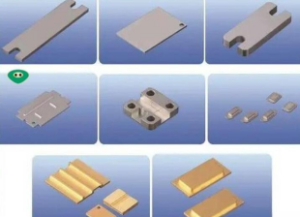

Electronic Packaging and Heat Sink Materials Material Introduction Electronic packaging involves placing a functional integrated circuit chip (including semiconductor integrated circuit chips, thin-film integrated circuit substrates, and hybrid integrated circuit chips) within a suitable housing. This provides the chip with a stable and reliable operating environment, protecting it from or minimizing external environmental influences, and ensuring stable and normal function. The packaging also serves as a means of connecting the chip’s input and output terminals to the outside, forming a complete integrated circuit with the chip. Electronic packaging materials are required to possess certain mechanical strength, good electrical properties, heat dissipation performance, and chemical stability. Different packaging structures and materials are selected depending on the type of integrated circuit and its intended use. Heat dissipation is an inevitable byproduct of power electronic devices and circuits. Heat sink materials help dissipate heat from the chip and transfer it to the surrounding air. Molybdenum-copper, tungsten-copper, CMC, and CMCC materials combine the low thermal expansion of molybdenum and tungsten with the high thermal conductivity of copper. They effectively dissipate heat from electronic devices, facilitating cooling of various products such as IGBT modules, RF power amplifiers, and LED chips. They can be used as insulating metal substrates, thermal control plates, heat sinks, and lead frames in large-scale integrated circuits and high-power microwave devices. Power Semiconductor Packages IGBT Modules Product Specifications We offer the following products for power electronic devices and circuits: Heat Sink Materials – Tungsten-Copper Alloy – Molybdenum-Copper Alloy – CMC, CMCC – Molybdenum Element Electronic Packaging Materials – AlSiC – AlSi Tungsten-Copper Alloy Product Advantages: The product has extremely low porosity, with a specific surface area measured by the BET method half that of domestic competitors (compared using 100 5*5*52mm samples). The product also exhibits excellent airtightness, passing a helium mass spectrometer leak test with a value of <5*10-9 Pa·m³/s. No activated sintering elements such as iron, nickel, cobalt, or manganese are added. This product offers excellent thermal conductivity and thermal expansion matching. It also boasts excellent machining accuracy, surface finish, and flatness. Electroplating is also available. Product Specifications: Bare tungsten copper die with nickel or gold plating. Molybdenum-copper alloy Product Advantages: Compared to tungsten copper alloys, molybdenum-copper alloys have a lower density. The product boasts extremely low porosity, with a surface area measured by the BET method half that of domestic counterparts (compared using 100 5*5*52mm samples). This product exhibits excellent airtightness and can fully

What Is The Most Commonly Used Titanium Alloy?

The three most commonly used titanium alloys are TC4, TC6, and TC11. They all have high specific strength, high temperature resistance, and oxidation resistance. Recently, some customers have called me with this question. Because our materials are used in different ways, we want them to be comfortable and user-friendly. I’d like to compare the various performance characteristics of these three materials. 1. TC4 Titanium Alloy Operating Temperature: -100-550°C, Density: 4.51 g/cm³. Room Temperature Mechanical Properties (25°C): Tensile Strength σb/MPa ≥ 895, Specified Residual Elongation Stress σr0.2/MPa ≥ 825, Elongation δ5% ≥ 10, Reduction of Area ψ% ≥ 25. High-Temperature Mechanical Properties (400°C): Tensile Strength: σb/MPa ≥ 620, Endurance Strength: σ100h/MPa ≥ 570. TC4 titanium alloy offers a range of advantages, including excellent corrosion resistance, low density, high specific strength, and good toughness and weldability. After solution strengthening treatment, the strength increase is minimal, reaching approximately 1100 MPa. The annealed strength is generally around 900 MPa. 2. TC6 Titanium Alloy Operating Temperature: 300°C, Density: 4.51 g/cm³. Room Temperature Mechanical Properties (25°C) Tensile strength σb/MPa ≥ 980, specified residual elongation stress σr0.2/MPa ≥ 840, elongation δ5(%) ≥ 10, reduction of area ψ(%) ≥ 25. High-temperature mechanical properties (400°C): Tensile strength: σb/MPa ≥ 735, endurance strength: σ100h/MPa ≥ 665. Advantages: Excellent microstructure and performance stability up to 300°C/5000h. High-temperature properties such as transient tensile strength, creep, and endurance at different temperatures are comparable to those of the double-annealed and isothermal-annealed conditions. TC6 titanium alloy semi-finished products that have undergone conventional annealing can meet the operating temperature requirements of aircraft structural components (below 300°C). 3. TC11 Titanium Alloy Operating Temperature: 500°C, Density: 4.51 g/cm³. Room Temperature Mechanical Properties (25°C): Tensile Strength: σb/MPa>1030, Specified Residual Elongation Stress σr0.2/MPa≥900, Elongation δ5(%)≥10, Reduction of Area ψ(%)≥30. High-Temperature Mechanical Properties (500°C): Tensile Strength: σb/MPa>685, Endurance Strength: σ100h/MPa≥640. Titanium Alloy Parts Wear Resistance Comparison: Both TC4 and TC11 alloys have poor wear resistance at 25°C, but exhibit very excellent wear resistance at 600°C. As can be seen above, TC4 does not have the high-temperature resistance of TC6 and TC11. TC11 has the highest strength, and of course, better wear resistance. Keyword: TC4 Titanium Alloy TC6 Titanium Alloy TC11 Titanium Alloy titanium alloys Titanium Alloy Parts

What Is TZM Material Equivalent To?

TZM is a molybdenum-based alloy, a commonly used high-temperature alloy among molybdenum-based alloys. Its English name is Titanium-Zirconium-Molybdenum Alloy. Main Components • Titanium (Ti): Approximately 0.50% in content. Titanium carbide (TiC) formed by titanium and carbon acts as a dispersed phase, strengthening the alloy. • Zirconium (Zr): Approximately 0.08% in content. Zirconium carbide (ZrC) formed by zirconium and carbon also acts as a dispersed phase, enhancing the alloy’s strength and hardness. • Carbon (C): Approximately 0.02% in content. It forms carbides with elements such as titanium and zirconium, strengthening the alloy. • Molybdenum (Mo): A matrix element, the balance. Molybdenum itself possesses properties such as a high melting point, high strength, and high hardness, providing the fundamental performance foundation for the alloy. Performance Characteristics TZM alloy features a high melting point, high strength, high elastic modulus, low linear expansion coefficient, low vapor pressure, excellent electrical and thermal conductivity, strong corrosion resistance, and excellent high-temperature mechanical properties. Main Applications In the military industry, it is used to manufacture valve bodies and rocket nozzles in torpedo engines. In the metallurgical industry, it can be used as a material for die-casting molds for ferrous and non-ferrous metals and for seamless stainless steel piercing plugs. In the electrical and electronic industry, it is used to manufacture cathodes, grids, and high-voltage rectifier components for electron tubes. In nuclear power equipment, it can be used in radiation shields, support frames, and heat exchangers. TZM alloy typically has a tensile strength of approximately 870 MPa, a yield strength of approximately 600 MPa, and an elastic modulus of approximately 320 GPa. Specific properties depend on the preparation method and parameters. TZM alloy is often produced using powder metallurgy, which includes alloy smelting, rotating electrode powder production, powder metallurgy (pressing and sintering), heat treatment, and machining. Powder metallurgy TZM materials have ultrafine grains. Existing methods for regulating the properties of TZM alloys primarily include solid solution strengthening (introducing various alloying elements), grain refinement (mechanical alloying of ductile iron powder), forming control (adjusting technology and process parameters), and particle strengthening (introducing ceramic particles such as TiC, ZrB2, ZrO2, Al2O3, and La2O3). These methods can achieve improvements in both tensile and compressive strength. During service, TZM alloys exhibit intergranular fracture. Porosity between grains and grain boundaries, as well as weakly bonded interfaces between second-phase particles, serve as sites for crack initiation and propagation. Therefore, defect control and grain boundary strengthening have become important research areas. With the continuous advancement

What Are The Uses Of Molybdenum Rod?

Molybdenum rod maintains zero deformation at 2200°C and is an invisible pillar in the aerospace, military, nuclear, and semiconductor industries. FOTMA utilizes TZM alloys and precision machining technology to create core components that withstand extreme operating conditions. Molybdenum rods are widely used in the following core industries due to their high melting point, high-temperature stability, and excellent mechanical properties: I. Core Industrial Applications of Molybdenum Rods Aerospace and Military Rocket Nozzle Throat Liners: Maintain zero deformation under 2200°C gas flow, ensuring propulsion system stability. Hypersonic Vehicle Leading Edge Components: Withstand 1648°C high-speed airflow and maintain structural rigidity. Vacuum and High-Temperature Equipment Vacuum Furnace Heating Elements and Supports: Leveraging a melting point of 2623°C, they achieve uniform heating and high-temperature structural stability. Sapphire Crystal Growth Furnace Support Components: Temperature control accuracy reaches ±1°C, increasing crystal transmittance to 99.8%. Energy Sector Nuclear Reactor Neutron Absorber Plates: Radiation-Resistant to Creep at 2000°C, Deformation <0.1%. Photovoltaic Glass Melting Furnace Stirring Rods: Liquid-Resistant to Corrosion at 1350°C, Annual Loss <3%. Electronics Industry Semiconductor Manufacturing Electrodes: Impurity Emission Rate <0.001ppm at 1800°C, Ensuring Chip Purity. Precision Electronic Device Frames: Extremely Low Thermal Expansion Coefficient, Ensuring High-Precision Equipment Stability. II. FOTMA Molybdenum Rod Technology Advantages Material Properties High-Temperature Resistant: TZM molybdenum alloy screws achieve a flexural strength of 930 MPa at 2200°C, 52% higher than ordinary molybdenum rods. Creep Resistance: Deformation <0.005mm after 1000 hours of continuous load at 1800°C. Precision Machining Nanoscale Precision: Straightness ≤ 0.01mm/m, threads reaching ISO 4H grade. Ultra-smooth surface finish: Polished to Ra ≤ 0.4μm, meeting semiconductor-grade cleanliness standards (outgassing rate <10⁻⁹ Pa·m³/s). Application Adaptability Full Customization: Covering sizes from M1.2 micro screws to Φ200mm large components, with 72-hour emergency delivery. Multi-Form Supply: In addition to standard rods, we also offer special-shaped connectors such as molybdenum screws and nuts. III. Typical Case Studies Aerospace: TZM molybdenum rods have survived 100 hot and cold cycles at 2200°C without cracking, certified for use in rocket engines. Industrial High-Temperature Equipment: Used in multi-layer heat shields for vacuum furnaces, they reflect 90% of heat radiation and reduce energy consumption by over 30%. Molybdenum rods are the “invisible pillar” of high-temperature, high-precision industrial applications. Through innovative materials (such as TZM alloys) and precision machining technologies, FOTMA provides core components that withstand extreme operating conditions for the aerospace, nuclear energy, semiconductor, and other industries. Keywords:molybdenum rod,TZM molybdenum alloy,molybdenum rods,TZM molybdenum alloy screws,ordinary molybdenum rods,molybdenum screws,molybdenum rods,TZM molybdenum rods,TZM molybdenum alloy

An alysis of the Outstanding Performance of Molybdenum-Copper Alloy and CMC Three-Layer Structure Materials

Analysis of the Outstanding Performance of Molybdenum-Copper Alloy and CMC Three-Layer Structure Materials 1. Molybdenum-Copper Alloy Properties and Applications Molybdenum-copper alloy, a pseudo-alloy crafted from two non-intersoluble metals, not only combines the unique properties of molybdenum and copper but also exhibits exceptional material properties. Its high thermal conductivity ensures efficient heat dissipation; its coefficient of thermal expansion can be flexibly adjusted to meet diverse requirements. Furthermore, its non-magnetic properties, low gas content, and excellent vacuum performance enable stable operation in a wide range of environments. Its excellent machinability and exceptional high-temperature performance make it a shining example in various industrial fields, including machinery, electrical power, electronics, and metallurgy. 1.1 ► Diverse Applications The high thermal conductivity, low coefficient of thermal expansion, and non-magnetic properties of molybdenum-copper alloy make it an excellent choice for applications in electronics and machinery. Its applications include heat dissipation materials for power amplifiers, the construction and maintenance of radio base stations, the manufacture of arcing and vacuum contacts for high- and medium-voltage switches or circuit breakers, heat dissipation components in electronic equipment, electrode materials in resistance welding processes, and the development and application of electronic packaging and heat sink materials. It excels in optimizing IGBT modules for electric vehicle (EV/HEV) engines and manufacturing high-performance lead frames. It can also be used in the design and manufacture of thermal control panels and heat sinks for military and civilian applications. 1.2 ► Product Specifications and Performance Parameters Molybdenum-copper alloys of various grades and proportions exhibit specific density, thermal conductivity, and thermal expansion coefficients. Mo85Cu15 to Mo50Cu50 exhibit excellent material properties at room to high temperatures. The following are some typical performance parameters: | Grade | Molybdenum Content (Wt%) | Copper Content (Wt%) | Density (g/cm³) | Thermal Conductivity (W/(M·K)) | Coefficient of Thermal Expansion (10-6/K) | |——-|————–|————–|————–|——————|———————| | Mo85Cu15 | 85±1 | Balance | 10.160–1.80 | 6.8 | 6.8 | | Mo80Cu20 | 80±1 | Balance | 9.9 | 170–190 | 7.7 | | Mo70Cu30 | 70±1 | Balance | 9.8 | 180–200 | 9.1 | | Mo60Cu40 | 60±1 | Balance | 9.66 | 210–250 | 10.3 | | Mo50Cu50 | 50 ±0.2 | Balance | 9.54 | 230–270 | 11.5 | 2. CMC Three-Layer Material Performance 2.1 ► Material Design and Advantages CMC (copper-molybdenum-copper) three-layer material, with its unique layered design and superior performance, is an ideal replacement for high-power electronic components. Its low coefficient of thermal expansion and high thermal conductivity are

INTERESTED IN JOINING OUR TEAM?

Fill out the form below and someone from our team will be in touch with you!

JOIN OUR NEWSLETTER

Sign up to see our newest products and exclusive offers!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074