ABOUT

Technology Of Cold-Rolling Tc4 Titanium Alloy Titanium Tube

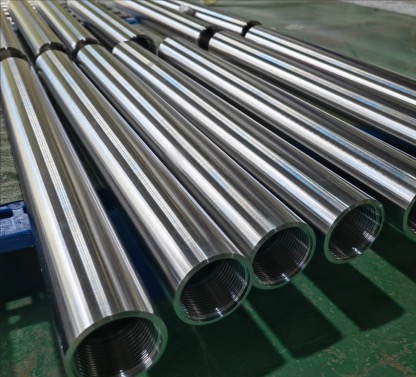

TC4 titanium alloy is one of the most widely used titanium alloys at present. It has high strength and good corrosion resistance, but in the seamless titanium tube market at home and abroad, titanium tube manufacturers (titanium tube manufacturers) and titanium tube suppliers (titanium tube suppliers) rarely provide seamless titanium tubes made of TC4 material.

TC4 titanium materials are mainly plates. In the current market, the available TC4 titanium tubes (titanium tube for sale) are mostly high-strength thick-walled tubes produced by hot extrusion or oblique perforation. Due to the complex processing equipment and cumbersome processes, the titanium tube price (titanium tube price) of such products remains relatively high, which limits their application range. For titanium tube factories (titanium tube factory) and companies, this has long been a technical bottleneck in expanding product lines—especially for titanium round tube (titanium round tube) products, which are in high demand in industrial fields.

The warm rolling process traditionally used requires improving traditional rollers by installing induction heating devices on tube rolling mills. This processing equipment has a complex structure, cumbersome processes, and high production costs. The main reason for this situation is that TC4 titanium alloy has high strength and is difficult to cold-roll form. To solve the key technology of cold-rolling forming of TC4 seamless tubes, schools and enterprises have jointly conducted a series of researches. For example, using the direct cold-rolling forming process to produce high-strength titanium alloy tubes not only greatly reduces production costs but also provides more choices for downstream customers who want to buy titanium tube (buy titanium tube), including wholesale titanium tube (wholesale titanium tube) and customized orders.

In the context of global industrial demand, China titanium tube (china titanium tube) enterprises (titanium tube company) have been actively breaking through technical barriers. This cold-rolling technology breakthrough is particularly significant for titanium tube china (titanium tube china) manufacturers, as it enables the production of custom titanium tube (custom titanium tube) and customized titanium tube (customized titanium tube) products with higher precision and lower costs. It also helps stabilize titanium tube stock (titanium tube stock) supply, ensuring that both standard and special-specification products can meet market needs in a timely manner.

The research results show that: In the case of small deformation billet opening, the wall thickness deviation is small and the surface roughness gradually decreases; in the case of large deformation billet opening, the wall thickness deviation is large, which will affect the wall thickness deviation of the pipe obtained by subsequent rolling. Under the same total deformation, the more rolling passes, the greater the elongation and hardness of the pipe, and the higher the strength, with comprehensive performance being good. When rolling with large deformation, the material flow is strip-shaped; when rolling with small deformation, the material flow is bundle-shaped. Under the same inter-pass heat treatment conditions and subsequent rolling processes, the organizational distortion of pipes formed by large-deformation billeting is more serious. Small-deformation billeting has little effect on the anisotropy of pipes; there is a certain fluctuation in the anisotropy of mechanical properties in multi-pass rolling.

This technological breakthrough not only improves the production efficiency of high-performance TC4 titanium tubes but also enriches the types of titanium tube stock (titanium tube stock) available—whether for standard specifications or customized titanium tube (customized titanium tube) products, it can meet the diverse needs of industries such as aerospace, petrochemicals, and medical equipment. For titanium tube suppliers (titanium tube suppliers) and manufacturers, this means stronger competitiveness in the global market, as they can now provide high-quality, cost-effective products to customers worldwide.

TC4 titanium materials are mainly available as plates. The TC4 titanium tubes (titanium tube for sale) on the market are mainly high-strength thick-walled tubes produced by hot extrusion or oblique perforation. Affected by complex production processes, the titanium tube price (titanium tube price) of such products has long been high, making it difficult for titanium tube stock (titanium tube stock) to meet large-scale demand. For titanium tube factories (titanium tube factory), especially China titanium tube (china titanium tube) enterprises, this has been a key constraint in expanding their product portfolios—especially for titanium round tube (titanium round tube) products, which are widely used in aerospace and chemical industries.

The traditional warm rolling process requires improving traditional rollers by installing induction heating devices on tube rolling mills. This processing equipment has a complex structure, cumbersome processes, and high production costs. The main reason for this situation is that TC4 titanium alloy has high strength and is difficult to cold-roll form. To solve the key technology of cold-rolling forming of TC4 seamless tubes, schools and enterprises have jointly conducted a series of researches. For example, using the direct cold-rolling forming process to produce high-strength titanium alloy tubes not only greatly reduces production costs but also provides more options for customers looking to buy titanium tube (buy titanium tube), including wholesale titanium tube (wholesale titanium tube) and customized orders.

This technological breakthrough is particularly significant for titanium tube companies (titanium tube company) aiming to expand their services. It enables the production of custom titanium tube (custom titanium tube) and customized titanium tube (customized titanium tube) products with higher precision, meeting the diverse needs of industries such as medical devices and energy. For titanium tube suppliers (titanium tube suppliers), it also means more stable titanium tube stock (titanium tube stock) supply, as the simplified process shortens production cycles.

In the global market, titanium tube china (titanium tube china) manufacturers have been striving to enhance their competitiveness. This cold-rolling technology not only improves product quality but also makes China’s titanium tube products more cost-effective in wholesale titanium tube (wholesale titanium tube) markets. Whether for standard specifications or special designs, the breakthrough ensures that titanium tube manufacturers (titanium tube manufacturers) can respond quickly to market demands.

The research results show that: In the case of small deformation billet opening, the wall thickness deviation is small and the surface roughness gradually decreases; in the case of large deformation billet opening, the wall thickness deviation is large, which will affect the wall thickness deviation of the pipe obtained by subsequent rolling. Under the same total deformation, the more rolling passes, the greater the elongation and hardness of the pipe, and the higher the strength, with comprehensive performance being good. When rolling with large deformation, the material flow is strip-shaped; when rolling with small deformation, the material flow is bundle-shaped. Under the same inter-pass heat treatment conditions and subsequent rolling processes, the organizational distortion of pipes formed by large-deformation billeting is more serious. Small-deformation billeting has little effect on the anisotropy of pipes; there is a certain fluctuation in the anisotropy of mechanical properties in multi-pass rolling.

Overall, this cold-rolling technology breakthrough not only optimizes the production process for TC4 titanium alloy tubes but also lays a solid foundation for titanium tube manufacturers and suppliers to expand into high-value markets, making high-quality, low-cost titanium tubes more accessible to global customers.

Keywords:

titanium tube manufacturers,titanium tube suppliers,titanium tube for sale,titanium tube price,titanium tube factory,titanium round tube,buy titanium tube,china titanium tube,custom titanium tube,customized titanium tube,titanium tube china,titanium tube company,titanium tube stock,wholesale titanium tube

We Exist to Make Your Projects Successful

Fill out the form below and someone from our team will be in touch with you!

FOTMA Delivers Professional Ultra-Dense Solutions, Lighter on Cost, Heavier on Performance.

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074