ABOUT

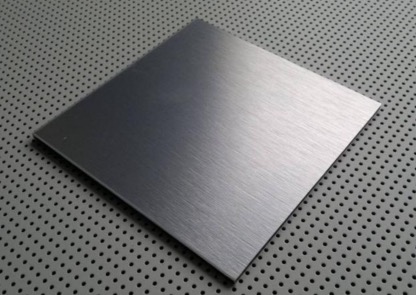

Ni200 Nickel Plate: Performance,Application and Processing Technology

Ni200 nickel plate is a high-purity, high-performance metal material. The following is a detailed introduction to it:

1. Composition and structure

Main composition: Ni200 nickel plate is mainly composed of nickel elements, with a nickel content of more than 99.6%, and the rest are trace impurity elements such as iron, carbon, silicon, sulfur, phosphorus, etc.

Structural characteristics: It has a face-centered cubic lattice structure, which gives it good strength and toughness.

2. Physical and chemical properties

Corrosion resistance: Ni200 nickel plate shows good corrosion resistance in a variety of corrosive media, especially in reducing media, its corrosion resistance is particularly outstanding. This makes Ni200 nickel plate widely used in chemical equipment, seawater desalination equipment and other fields.

Electrical conductivity and thermal conductivity: Ni200 nickel plate has excellent electrical conductivity and thermal conductivity, and its electrical conductivity and thermal conductivity are relatively high. This makes Ni200 nickel plate widely used in electronic components, vacuum devices, precision instruments and other fields.

Mechanical properties: Ni200 nickel plate has good mechanical properties, including tensile strength, yield strength, elongation, etc. Although its mechanical properties are relatively low (such as tensile strength of 380 MPa and yield strength of 105 MPa), it still has good processing performance and mechanical properties, and can be used to manufacture parts of various shapes through cold processing and slight processing.

3. Application fields

Chemical industry: Ni200 nickel plate is widely used in the chemical industry, mainly used to manufacture corrosion-resistant chemical equipment, pipelines, valves, etc. Its good corrosion resistance can ensure the long-term stable operation of equipment in corrosive media.

Electronic field: Ni200 nickel plate also has important applications in the electronics field, mainly used to manufacture electronic components, electric vacuum devices, etc. Its excellent electrical conductivity and thermal conductivity can meet the needs of electronic components for high-performance materials.

Aerospace field: In the aerospace field, Ni200 nickel plate is used to manufacture high-temperature structural parts, heat shields, etc. Its good high temperature performance and corrosion resistance can ensure the stable operation of equipment in extreme environments.

Other fields: Ni200 nickel plate is also widely used in medical, nuclear industry and other fields. For example, in the medical field, Ni200 nickel plate is used to manufacture medical devices such as artificial joints and dental implants; in the nuclear industry, Ni200 nickel plate is used to manufacture protective screens, heat exchangers and other equipment for nuclear reactors.

IV. Processing and heat treatment process

Casting process:

Melting: Since Ni200 has a high melting point (about 1453°C), it is necessary to use a high-efficiency arc furnace or induction furnace for melting.

Impurity removal: It is easy to mix insoluble impurities during the smelting process, and conventional degassing and slag treatment processes are required to ensure purity.

Casting: Attention should be paid to controlling the casting speed and temperature to avoid defects such as cracks and segregation.

Hot processing: Hot processing is an important means of Ni200 forming, including rolling, forging and extrusion.

Heating: Generally, heating is performed above 1200°C to ensure that the material has sufficient plasticity.

Forging: Forging is suitable for temperatures between 800 and 1200°C. Temperature drops should be avoided during processing to prevent the generation of internal stress.

Rolling: Hot rolling is usually carried out at 1000-1200°C. The rolling speed and reduction should be controlled to ensure the homogeneity and surface quality of the plate or tube.

Cold working: Cold working of Ni200 mainly includes cold rolling, drawing and cutting.

Cold rolling: It is carried out at room temperature and is usually used to prepare thin plates and strips. It requires multiple multi-directional rolling to gradually reach the required thickness.

Drawing: It is mainly used to make fine diameter wires. It needs to be stretched gradually to reduce the risk of breakage.

Cutting: Ni200 has obvious work hardening and usually requires softening heat treatment before cutting. The cutting speed should be moderate, and the cutting fluid should have good lubrication and cooling properties.

Heat treatment: Heat treatment is an important means to adjust and improve the performance of Ni200, including annealing, aging treatment and stress relief treatment.

Annealing: The annealing temperature is generally 700~900°C. The main purpose is to restore the plasticity and toughness after cold working and eliminate internal stress.

Aging treatment: Aging treatment helps to improve the strength and hardness of the material, usually carried out in the range of 400~600°C.

Stress relief treatment: Suitable for large-size structural parts, usually carried out at 300~500°C to eliminate the residual stress introduced by hot working and cold working.

V. Surface treatment and protection

Although Ni200 itself has good corrosion resistance, in some special environments, proper surface treatment can further enhance its performance. Common surface treatment methods include:

Passivation treatment: A passivation film is generated on the surface of Ni200 by chemical methods to improve its corrosion resistance.

Plating treatment: A layer of other metals such as chromium and iron is plated on the surface of Ni200 to improve wear resistance and corrosion resistance.

Oxide film protection: A nickel oxide film is generated by high-temperature oxidation, which is also a common surface protection method.

Keywords:

nickel plate

We Exist to Make Your Projects Successful

Fill out the form below and someone from our team will be in touch with you!

FOTMA Delivers Professional Ultra-Dense Solutions, Lighter on Cost, Heavier on Performance.

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074