ABOUT

Tungsten-copper Composite Material: An Efficient Electrode Material For Multiple Applications

Application of tungsten-copper composite materials in EDM and welding processing

Tungsten, a metal element, is theoretically considered an ideal electrode material. Its excellent strength, density and high hardness characteristics, coupled with a melting point close to 3400°C, make the tungsten electrode extremely low in practical applications. For this reason, tungsten-copper composite materials play a vital role in the field of EDM and welding.

However, although pure tungsten has many advantages in theory, it faces two major problems when used as an electrode: one is that it is extremely difficult to process, and the other is that it is relatively expensive. In order to overcome these challenges, scientists have cleverly combined the excellent properties of pure copper, such as plasticity and high conductivity, to develop tungsten-copper composite materials. This material not only retains the high strength, high density and high hardness of tungsten, but also incorporates the processing advantages of copper, making it an ideal electrode choice in the field of EDM and welding.

Tungsten-copper composite materials not only have excellent electrical conductivity and high softening temperature, but also have arc corrosion resistance and high wear resistance, which significantly extends their service life and greatly reduces the frequency of electrode correction. In addition, it can effectively save the cost and maintenance of processing tools while improving productivity, making it an ideal advanced welding material. Next, we will explore the wide range of uses of tungsten copper.

1. Advanced EDM electrode materials:

During the electro-erosion process, ordinary electrodes tend to have large losses and slow processing speeds for molds such as tungsten steel (hard alloy), high-speed steel, and high-temperature resistant super-hard alloy. However, tungsten copper materials can significantly improve the accuracy of the processed parts due to their excellent electro-erosion speed, low loss rate, precise electrode shape, and excellent processing performance.

2. Advanced welding electrode materials:

Combining the dual advantages of tungsten and copper, this type of material is not only resistant to high temperatures and arc ablation, but also has excellent resistance to fusion welding and low cut-off performance. Its high strength, high specific gravity, and excellent electrical and thermal conductivity make it an ideal choice for processes such as spot welding, butt welding, butt welding, and projection welding. In addition, the material is easy to cut and has unique sweat cooling and anti-adhesion properties, making it particularly suitable for applications that require wear resistance and high temperature stability.

3. Application materials in the electronics field:

Tungsten copper plays an indispensable role in the electronics field due to its excellent physical and electrical properties. Its high strength, excellent electrical and thermal conductivity, and small thermal expansion coefficient make it an ideal choice for electronic engineers. It is widely used in various power electronic devices, such as rectifiers, thyristors, power modules, etc., as well as high-power applications such as laser diodes and microwave tubes. In addition, tungsten copper also plays an important role in microelectronic devices such as computer CPUs and DSP chips.

In high-tech fields such as microwave communications, automatic control, power conversion, and aerospace, the importance of tungsten copper cannot be ignored. At present, it is mainly used as a heat sink for high-power microwave tubes, high-power laser diodes, and some high-power integrated circuit modules to ensure that these key components can work stably in high-temperature environments.

4. Application of electrical contact materials:

Tungsten copper electrical contacts have a long history of application in the field of high-voltage switches, especially in high-voltage and high-current circuit breakers, where their use is particularly significant. Such circuit breakers include high-voltage, oil-free, low-oil circuit breakers, SF6 circuit breakers, as well as disconnectors and heavy-duty contactors.

5. Medical and industrial applications:

Due to its unique properties, tungsten copper materials are widely used in the medical field for shielding against X-rays and G-rays to ensure the safety and protection of medical equipment. In addition, it also plays an important role in the civilian industry. For example, as a high-density alloy counterweight, it is widely used in the manufacture of products such as smartphone vibrators, weights of automatic mechanical watches, golf club bodies, and darts.

6. Diversified applications of tungsten copper alloys

Tungsten copper alloys, with their unique physical and chemical properties, play an important role in many fields. From the radiation shielding of medical equipment to the manufacture of civilian products such as smartphone vibrators and weights of automatic mechanical watches, tungsten copper alloys have demonstrated their indispensable value.

7. Resistance welding electrodes:

Tungsten copper alloy combines the excellent properties of tungsten and copper, making it perform well in high temperature environments, while also having arc erosion resistance, high strength, high specific gravity, and excellent electrical and thermal conductivity. Its unique cutting performance and sweating cooling characteristics further enhance its durability and reliability in practical applications. For this reason, tungsten copper alloy is often selected as an ideal material for manufacturing projection welding and butt welding electrodes, especially in situations where a certain degree of wear resistance and high temperature resistance are required.

8. High-voltage discharge tube electrodes:

During the operation of high-voltage vacuum discharge tubes, the contact material will experience a sharp rise in temperature in a very short period of time, reaching several thousand degrees Celsius. Tungsten copper alloy provides stable performance for discharge tubes with its excellent ablation resistance, high toughness, and good electrical and thermal conductivity.

9. High-performance applications in the aerospace field:

Tungsten copper alloy plays a key role in the aerospace industry with its high density, excellent sweating cooling characteristics, excellent high-temperature strength and excellent erosion and ablation resistance. It is often used as a nozzle throat lining for missiles and rockets, and is also widely used in multiple key components such as gas rudder components, air rudders, head covers and counterweights.

10. Application of vacuum contact materials:

In a vacuum environment, the contact material needs to have good machinability and thermal shock resistance. During the contact and disconnection process, due to the action of the arc, the contact material will experience a sharp rise in temperature in a very short time, sometimes even up to several thousand degrees Celsius.

11. Electrode materials for EDM:

In EDM, the selection of electrode materials is crucial. In the early days, copper or graphite was often used as electrode materials. Although they were affordable, they had poor ablation resistance. Today, tungsten copper electrodes have gradually become the mainstream choice.

Tungsten copper electrodes are not only resistant to high temperatures and have high high-temperature strength, but also have excellent arc ablation resistance. At the same time, its excellent electrical and thermal conductivity and rapid heat dissipation provide reliable protection for EDM.

12.FOTMA tungsten copper materialshttps://tungstenchina.com/product/copper-tungsten-electrode/

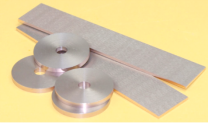

We provide a variety of specifications of tungsten copper plate materials, including W70, W75 and W80, with a thickness range of 2mm to 30mm and a length and width of 100mm×100mm. In addition, we can also customize special specifications according to customer needs.

Tungsten copper threaded electrode

We offer two specifications of tungsten copper threaded electrode, one with 30mm thread length and 50mm total length, and the other with 40mm thread length and 60mm total length. These electrodes are made of W70 material, with thread diameters ranging from 3mm to 12mm, to meet your different needs.

Tungsten copper rod

We offer three specifications of tungsten copper rods, W70, W75 and W80, with diameters ranging from 1 to 100mm and lengths of 200mm. The tolerance of these tungsten copper rods is controlled within ±0.05mm, and the bending strength reaches 700Mpa. Specifically, the density of W70 tungsten copper rod is 13.8-14g/cm3 and the hardness is 185HV; while the density of W75 and W80 tungsten copper rods are both 15-15.2g/cm3, and the hardness reaches 195HV and 210HV respectively. In addition, W75 tungsten copper rod also has an excellent softening temperature of up to 900℃. These tungsten copper rods can be widely used in various demanding occasions.

Keywords:

tungsten-copper composite materials,tungsten copper materials,tungsten copper,Tungsten copper,tungsten copper materials,,tungsten copper alloys,tungsten copper electrodes

We Exist to Make Your Projects Successful

Fill out the form below and someone from our team will be in touch with you!

FOTMA Delivers Professional Ultra-Dense Solutions, Lighter on Cost, Heavier on Performance.

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074