ABOUT

Titanium Foil: Wide Application Of high-performance Metal Materials

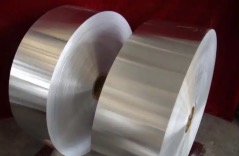

TA1, TA2, TA3, TA4, GR5, TC4, GR1, GR2, titanium foil is a high-quality metal material. The following is a detailed introduction to titanium foil:

1. Definition and specifications

Titanium foil refers to titanium plates, strips, coils or sheets with a thickness of less than or equal to 0.1mm. Its width can be cut according to user needs, but the maximum width of rolled titanium foil is usually about 600mm. In addition to thickness, the specifications of titanium foil can also be measured by weight per unit area, such as g/m² or oz/ft², etc. The larger the value, the greater the thickness.

2. Characteristics and performance

High strength: Titanium has a better strength-to-density ratio than other metals, so it can be made into components with high strength, good rigidity and light weight. This makes titanium foil widely used in aerospace, navigation, nuclear power and other fields, such as engines, frames, skins, fasteners and landing gear for aircraft.

Excellent corrosion resistance: Titanium alloys have better corrosion resistance in humid air and seawater than stainless steel. Titanium has great resistance to pitting corrosion, acid corrosion and stress corrosion, and can resist corrosion from alkali, chloride, chlorinated organic matter, sulfuric acid, nitric acid and other substances.

High and low temperature resistance: The application temperature of titanium is higher than that of aluminum alloy, and it can work for a long time at 450~500℃. At the same time, titanium alloy can still maintain its mechanical properties under low or ultra-low temperature conditions, so it is a good low-temperature structural material.

Environmental protection and thermal conductivity: The thermal conductivity of titanium is lower than that of carbon steel or copper, but titanium has very good corrosion resistance, so the thickness of titanium can be greatly reduced, and the heat exchange mode is drop-by-drop condensation between titanium and steam, which reduces the heat transfer resistance and makes the thermal conductivity of titanium better.

Non-magnetic: Titanium is a non-magnetic metal and cannot be magnetized in a large magnetic field.

Biocompatibility: Titanium is non-toxic and compatible with blood, and is widely used in the medical field.

3. Application fields

Titanium foil sheet is widely used in many fields due to its unique properties:

Aerospace: Used to manufacture various parts of aircraft, such as engines, frames, skins, etc.

Navigation: used to manufacture corrosion-resistant parts of ships.

Nuclear power: used to manufacture corrosion-resistant and high-temperature resistant parts in nuclear reactors.

Electronics: used to manufacture electronic components such as speakers and capacitors.

Chemical industry: used to manufacture corrosion-resistant chemical equipment and pipelines.

Medical and pharmaceutical: used to manufacture medical devices and pharmaceutical equipment, such as scalpels, implants, etc.

Others: also used in clocks, glasses, jewelry, sporting goods, mechanical equipment, electroplating equipment, environmental protection equipment, golf and precision machining.

IV. Production method

The production method of titanium foil factory mainly includes the following steps:

Raw material preparation: titanium powder is used as the main raw material, and spherical particles are prepared through high-temperature reaction.

Preparation of titanium plate: Arrange the titanium particles and pre-press them into large titanium plates.

Casting: Put the titanium plate into a vacuum furnace for melting, control the temperature and atmosphere, and make it into a specific shape in the mold.

Hot rolling: Use a coiler to raise the temperature of the cast plate, then finely roll, spread, heat and soften, control the thickness, and finally form titanium foil.

Surface treatment: Surface treatment of titanium foil to improve its performance.

Quality inspection: Inspect the finished titanium foil to ensure that its quality meets the standard requirements.

Titanium foil has attracted much attention due to its unique properties and wide range of applications. With the continuous advancement of technology and people’s in-depth understanding of the performance of titanium foil, the application field of titanium foil will be more extensive. As a professional titanium foil manufacturer in China, we are happy to provide you with high-quality products and services.

Keywords:

titanium foil roll

We Exist to Make Your Projects Successful

Fill out the form below and someone from our team will be in touch with you!

FOTMA Delivers Professional Ultra-Dense Solutions, Lighter on Cost, Heavier on Performance.

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074