ABOUT

High-purity Tungsten Wire: The Crossover King From Traditional Lighting To Modern Medicine

In the vast starry sky of material science, there is a shining star – high-purity tungsten wire. This seemingly ordinary metal wire has amazing physical properties, which makes it shine in many high-tech fields. Today, let us unveil the mystery of high-purity tungsten wire and explore how it has crossed a hundred years of time and space, from the incandescent lamp of Edison’s era to the precision world of modern surgical robots.

“Hexagonal Warrior” in the material world

The most commendable feature of high-purity tungsten wire is its amazing high temperature resistance. The melting point of 3410℃ makes it stand out from the crowd, which is more than twice the melting point of ordinary steel. It is this feature that makes tungsten wire an ideal filament material for incandescent bulbs at the beginning of its invention, opening a new era of human lighting revolution.

In addition to high temperature resistance, pure tungsten wire also has excellent mechanical properties. The diameter is as thin as a hair but can maintain the strength of steel wire. This unique strength-to-weight ratio makes it a darling in the field of precision manufacturing. In the photovoltaic industry, the service life of diamond wire made of tungsten wire can reach 10 times that of stainless steel wire, which greatly reduces the cost of silicon wafer cutting.

“Hidden Champion” of Photovoltaic Industry

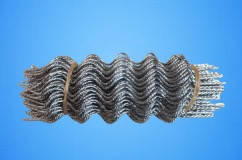

In the pursuit of clean energy today, the photovoltaic industry has put forward unprecedented high standards for materials. Thin tungsten wire has become a key material in the silicon wafer cutting process due to its excellent performance. Traditional stainless steel wire is easy to wear and deform during the cutting process, while tungsten wire diamond wire can maintain stable cutting accuracy, significantly improving the yield rate and production efficiency of silicon wafers.

What is even more surprising is that the diameter of tungsten wire can be extremely fine, which creates conditions for the production of thinner silicon wafers. Thinning can not only save silicon material costs, but also improve the flexibility of battery cells, opening up a broader space for photovoltaic applications. It can be said that tungsten wire plays an indispensable role in the road of improving quality and reducing costs in the photovoltaic industry.

Precision “nerves” in the medical field

When tungsten wire technology meets modern medicine, an exciting chemical reaction occurs. Medical engineers use ultra-fine tungsten wire with a diameter of only 0.0127 mm to create a sensitive “nervous system” for surgical robots. These tungsten wires, thinner than a hair, conduct precise mechanical movements, allowing surgeons to perform micron-level surgical operations.

Compared with traditional stainless steel materials, the durability and fatigue resistance of tungsten wires greatly extend the service life of surgical instruments. In precision surgeries such as heart stent implantation and neurosurgery, tungsten wire instruments have shown irreplaceable advantages. Its biocompatibility has also been strictly verified to ensure that it will not cause adverse reactions to the human body.

“Fierce Eyes” of Industrial Inspection

In the field of industrial inspection, tungsten wire also shows its prowess. The 5.2 mm flexible tungsten wire tube can easily penetrate into complex machinery such as engines, providing engineers with clear images of internal conditions. This endoscope technology is widely used in aviation, automobiles, energy and other industries, greatly improving the efficiency and accuracy of equipment maintenance.

The flexibility of tungsten wire enables it to adapt to various complex paths, while its strength ensures that it will not deform in a small space. Inspectors can accurately locate the fault point through tungsten wire endoscopes, avoiding the high cost and time waste caused by traditional disassembly inspections.

From scientists breaking through the technical difficulties of powder metallurgy in 1909 to adding rhenium to improve fracture resistance in modern times, the manufacturing process of tungsten wire has been constantly innovating. This ancient yet young material is showing its unique value in more emerging fields such as 5G communications, semiconductors, aerospace, etc. When we look back at the history of material development, the legendary story of high-purity tungsten wire tells us: real innovation often comes from the in-depth exploration and cross-border application of traditional materials. As one of the leading China tungsten wire manufacturers and suppliers, we are glad to work with you to achieve your industrial goals.

Keywords:

We Exist to Make Your Projects Successful

Fill out the form below and someone from our team will be in touch with you!

FOTMA Delivers Professional Ultra-Dense Solutions, Lighter on Cost, Heavier on Performance.

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074