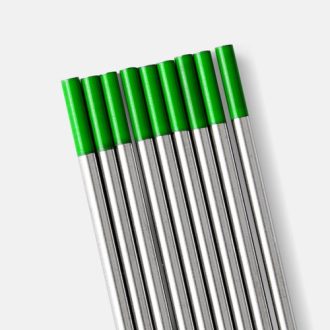

WZ Zirconiated Tungsten Electrodes

|

Parameter |

Zirconiated Tungsten (WZr) | Pure Tungsten (W) | Thoriated Tungsten (WT20) |

| Dopant | ZrO₂ (0.3–0.5%) | None |

ThO₂ (1.7–2.2%) |

|

Radioactivity |

None | None | Present (α-rays) |

| Optimal Current Type | AC | AC/DC (low efficiency) |

DC |

|

Current Range (AC) |

150–600 A | 50–200 A |

Not recommended |

Zirconiated Tungsten Electrodes (WZ): High-Performance AC Welding Solutions for Demanding Industrial Applications

Zirconiated tungsten electrodes (WZ) are engineered for superior performance in alternating current (AC) welding, particularly in aluminum and magnesium alloy processing. By incorporating 0.3–0.5% zirconium oxide (ZrO₂), these electrodes deliver exceptional arc stability, contamination resistance, and longevity, making them a preferred choice for industries requiring precision and reliability in high-current environments.

Advantages of WZ Tungsten Electrode

- Optimized for AC Welding

-

- Stable Arc: ZrO₂ enhances arc ignition and stability in AC mode, reducing tungsten spitting and ensuring smooth weld pools.

- High Current Capacity: Supports 150–600 A in AC applications, ideal for thick aluminum plates and heavy-duty welding.

- Contamination Resistance

-

- Self-Cleaning Action: Maintains a clean tip during welding, minimizing impurities in reactive metals like aluminum and magnesium.

- Reduced Tungsten Inclusion: Doped zirconium improves tip integrity, lowering the risk of weld defects.

- Non-Radioactive & Eco-Friendly

-

- Thorium-Free: Safe for operators and compliant with global environmental regulations (RoHS, REACH).

- Easy Disposal: No special handling required for spent electrodes.

- Extended Service Life

-

- High-Temperature Durability: Withstands repeated thermal cycling, offering 2x longer lifespan than pure tungsten electrodes.

- Low Wear Rate: ZrO₂ doping reduces tip erosion, even at high currents.

Technical Specifications Comparison

| Parameter | Zirconiated Tungsten (WZr) | Pure Tungsten (W) | Thoriated Tungsten (WT20) |

| Dopant | ZrO₂ (0.3–0.5%) | None | ThO₂ (1.7–2.2%) |

| Radioactivity | None | None | Present (α-rays) |

| Optimal Current Type | AC | AC/DC (low efficiency) | DC |

| Current Range (AC) | 150–600 A | 50–200 A | Not recommended |

| Electron Work Function (eV) | 3.5–4.0 | 4.5–5.0 | 2.8–3.2 |

| Typical Diameter (mm) | 1.6, 2.4, 3.2, 4.8 | 1.0–6.0 | 1.6–6.0 |

| Price ($/piece, Φ2.4mm) | 7–10 | 4–6 | 6–10 |

Zirconiated Electrodes Application

- Aluminum Fabrication: Shipbuilding, automotive radiators, and aerospace structural components.

- Magnesium Alloy Welding: Lightweight machinery and electronics enclosures.

- Heavy Industry: Pressure vessel manufacturing and pipeline construction.

- Repair & Maintenance: High-current repair of cast aluminum parts and heat exchangers.

Customization & Services

- Dimensions: Diameters 0.5–10.0 mm, lengths 75–500 mm, with tapered or truncated tip options.

- Surface Treatments:

- Mirror Polishing: For reduced arc wander in precision welding.

- Oxidation-Resistant Coating: Extends shelf life in humid environments.

- Certifications: AWS A5.12M, ISO 6848, and material traceability reports.

- Technical Support: Welding parameter optimization and on-site training.

Why Choose FOTMA Zirconiated Tungsten Electrodes?

- Premium Material: 99.95% pure tungsten with uniform ZrO₂ dispersion for consistent performance.

- Rapid Turnaround: Standard sizes ship in 24 hours; custom orders fulfilled in 5–7 days.

- Global Compliance: Meet OSHA, RoHS, and REACH standards for international shipments.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074