WT Thoriated Tungsten Electrodes

|

Diameter (mm) |

Recommended Current (A) | Typical Applications |

| 1.6–2.4 | 50–150 |

Thin sheet welding, precision repairs |

|

3.2–4.0 |

200–400 | Pipe welding, pressure vessel fabrication |

| 4.8–6.4 | 400–600 |

Shipbuilding/nuclear thick-plate multi-pass welding |

Thoriated Tungsten Electrodes (WT Tungsten Electrodes): The Premier Choice for High-Stability DC Welding

Thoriated tungsten electrodes, composed of 97–98% tungsten and 1–2% thorium oxide (ThO₂) , are essential for DC TIG (Tungsten Inert Gas) welding processes. Their superior electron emission capability and exceptional high-temperature resistance make them ideal for welding high-melting-point metals like stainless steel and nickel-based alloys. Despite containing trace amounts of radioactive thorium, they comply with international safety standards (e.g., ISO 6848) under regulated use and are widely adopted in heavy industry and advanced manufacturing sectors.

WT Electrodes Applications

- Stainless Steel Welding:

- In DC TIG welding of austenitic stainless steel and duplex steels, thoriated electrodes deliver stable low-voltage arcs, minimizing spatter and ensuring dense, porosity-free welds.

- High-Current Welding:

- Supports 200–600A currents (depending on diameter and cooling), ideal for thick-plate welding (>10mm), pressure vessel fabrication, and other high-load scenarios.

- Automated Production Lines:

- High-frequency arc ignition and extended lifespan design make them compatible with robotic welding systems, enhancing continuous operation efficiency.

Performance Advantages of Thoriated Electrodes

- Outstanding Electron Emission:

- Thorium oxide doping reduces work function by 30% , achieving low ignition voltage (10–15V) and significantly improving arc-starting success rates.

- High-Temperature Stability:

- Melting point of 3,300°C; outperforms pure tungsten in resistance to arc erosion under sustained high currents, extending lifespan by 50% .

- Broad Current Adaptability:

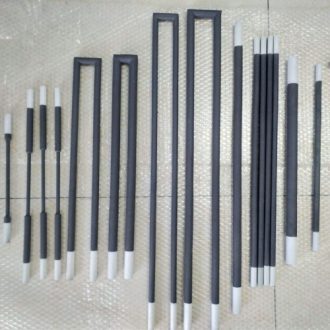

- Diameter range: 1.6–6.4mm; current coverage: 50–600A, suitable for applications from precision welding to heavy industrial thick-plate welding.

- Controlled Radioactivity Management:

- Thorium content strictly regulated to 1–2% , compliant with OSHA and IAEA low-risk standards, with dedicated disposal guidelines provided.

| Diameter (mm) | Recommended Current (A) | Typical Applications |

| 1.6–2.4 | 50–150 | Thin sheet welding, precision repairs |

| 3.2–4.0 | 200–400 | Pipe welding, pressure vessel fabrication |

| 4.8–6.4 | 400–600 | Shipbuilding/nuclear thick-plate multi-pass welding |

Material Science and Manufacturing

- Precision Doping Technology:

Thorium oxide nanoparticles are uniformly dispersed in the tungsten matrix via powder metallurgy combined with hot isostatic pressing (HIP) , achieving material density >99.5%. - Surface Optimization:

Laser-ground tips with 20°–60° taper angles adapt to diverse arc profiles; select models feature anti-oxidation copper plating. - Radioactivity Control:

Closed production processes ensure surface radiation dose <1μSv/h (below natural background levels), with MSDS safety certifications provided.

Comparison with Other Electrodes

| Property | Thoriated (2% ThO₂) | Pure Tungsten | Ceriated (2% CeO₂) |

| Electron Emission | Optimal (low work function) | Poor (requires HF ignition) | Good |

| DC Welding Performance | Stable arc, deep penetration | Not applicable | Moderate |

| Radioactivity Risk | Low-level (requires compliant handling) | None | None |

| Typical Use Cases | Stainless steel/nickel alloy DC welding | Aluminum AC welding | General-purpose (mild steel, titanium) |

Usage and Maintenance Guidelines

- Safety Protocols:

- Wear gloves during welding to avoid direct contact; dispose of used electrodes as radioactive waste.

- Tip Preparation:

- Grind tips with dedicated wheels to maintain symmetrical taper angles, preventing arc deflection.

- Gas and Parameter Optimization:

- Use argon gas with purity ≥99.996% at 15–25 L/min flow rate; avoid exceeding 120% of rated current.

Choose thoriated tungsten electrodes—leveraging cutting-edge material science and stringent quality control to ensure reliability in demanding DC welding applications!

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074