WL Lanthanated Tungsten Electrodes

|

Diameter (mm) |

Recommended Current Range (A) | Typical Applications |

| 1.0–2.4 | 50–200 |

Thin plate welding (<5mm), precision parts |

|

3.2–4.0 |

200–350 | Automotive chassis, pipeline joints |

| 4.8–6.4 | 350–500 |

Heavy machinery structures, thick plate multi-pass welding |

WL Lanthanated Tungsten Electrodes: Versatile and Eco-Friendly Welding Solutions

Lanthanated tungsten electrodes, composed of 97–98% tungsten and 1–2% lanthanum oxide (La₂O₃) , are high-efficiency materials for TIG welding that excel in both DC and AC applications. Their unique high electron emission capability and non-radioactive, environmentally friendly properties make them ideal for welding stainless steel, carbon steel, titanium alloys, and more, perfectly aligning with modern manufacturing demands for both efficiency and safety.

Applications

- Multi-Material Welding:

- Deliver stable arcs and deep penetration in DC TIG welding of stainless steel, carbon steel, and titanium alloys, minimizing weld defects. Also suitable for AC welding of aluminum thin plates.

- Medium-to-High Current Operations:

- Support a broad current range of 100–500A (depending on diameter and cooling conditions), ideal for welding medium-thick plates in automotive components, pressure pipelines, and similar applications.

- Automation and Robotic Welding:

- Low ignition voltage and extended service life make them compatible with high-speed automated production lines, reducing downtime for maintenance.

Performance Advantages

- Superior Electron Emission:

- Lanthanum oxide doping reduces work function by 25% , requiring only 12–18V for arc ignition and improving ignition success rates by 30%.

- Non-Radioactive & Eco-Friendly:

- Zero radioactivity risk (vs. thoriated electrodes), compliant with RoHS and ISO 6848 standards, with no special disposal required.

- Broad Current & Polarity Compatibility:

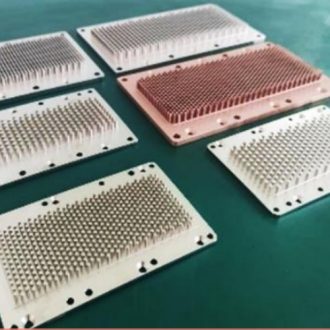

- Available in diameters of 1.0–6.4mm, compatible with DCEN (Direct Current Electrode Negative) and AC, covering applications from precision electronics to heavy machinery.

- High-Temperature Resistance:

- Melting point of 3,370°C, with 40% longer lifespan than ceriated electrodes under sustained high-current operations due to improved erosion resistance.

| Diameter (mm) | Recommended Current Range (A) | Typical Applications |

| 1.0–2.4 | 50–200 | Thin plate welding (<5mm), precision parts |

| 3.2–4.0 | 200–350 | Automotive chassis, pipeline joints |

| 4.8–6.4 | 350–500 | Heavy machinery structures, thick plate multi-pass welding |

Material Science & Manufacturing

- Nanoscale Doping Technology:

Lanthanum oxide nanoparticles are evenly dispersed in the tungsten matrix via plasma spraying, ensuring consistent electron emission and reducing arc fluctuation. - Precision Machining:

Tips are CNC-ground to a 15°–45° taper angle for adaptable arc focusing; some models feature nickel-plated surfaces for oxidation resistance. - Eco-Conscious Production:

Closed-loop manufacturing with exhaust and wastewater recycling, compliant with ISO 14001 environmental management standards.

Comparative Advantages vs. Other Electrodes

| Property | Lanthanated (2% La₂O₃) | Thoriated (2% ThO₂) | Ceriated (2% CeO₂) |

| Electron Emission | Excellent (low ignition voltage) | Excellent (requires high-frequency assist) | Good |

| Radioactivity Risk | None | Low-dose (requires special handling) | None |

| DC Welding Performance | High penetration, stable arc | Excellent | Moderate |

| AC Welding Suitability | Good (supports aluminum thin plates) | Not applicable | Best |

| Typical Use Cases | Multi-scenario welding (stainless steel/titanium) | High-load DC stainless steel welding | AC aluminum welding, general-purpose |

Usage & Maintenance Guidelines

- Tip Preparation:

- Grind with diamond wheels to maintain taper symmetry and prevent arc deviation; re-sharpen tips every 4 hours of welding.

- Gas Shielding Optimization:

- Use argon gas with purity ≥99.99% and flow rate of 12–20 L/min; add 25% helium for thicker plates to enhance penetration.

- Current Limits:

- Avoid prolonged operations above 120% rated current to prevent electrode overheating and oxidation.

Choose lanthanated tungsten electrodes for eco-friendly, high-efficiency, and versatile performance—redefining welding reliability!

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074