WCu Tungsten Copper alloy

|

Industry |

Critical Demands | FOTMA WCu Advantage |

| Microelectronics | Thermal management in 5G/RF chips |

Ultra-low porosity ensures leak-free encapsulation for GaN/SiC devices. |

|

Resistance Welding |

Electrode longevity in automotive lines | High conductivity (45–50% IACS) + wear resistance double lifespan vs. pure Cu. |

|

EDM Tooling |

Precision spark erosion in hard alloys |

Fine-grained structure enables mirror EDM surfaces (Ra ≤0.1µm). |

| Military | Hypersonic vehicle “sweating” thermal shields |

Customized WCu porosity achieves active cooling under 2000°C. |

|

Industrial Molds |

High-pressure die casting (Al/Mg) |

High red hardness safeguards tool geometry for 100K+ cycles. |

FOTMA tungsten copper (WCu) alloy delivers near-full density, zero-defect microstructure, and helium-leak-tight integrity (<5×10⁻⁹ Pa·m³/s), rivaling top global competitors. Engineered for extreme thermal conductivity, wear resistance, and structural stability, it is the ultimate solution for high-reliability applications in microelectronics, defense, and industrial tooling.

Alloy Copper Tungsten Breakthrough Material Properties:

- Unmatched Structural Integrity

- Density ≥99.5% : Achieved via vacuum sintering and HIP (Hot Isostatic Pressing), eliminating porosity and ensuring superb thermal/electrical conductivity.

- Ultra-Fine Grain: Average grain size 3–8µm (tested via SEM), enhancing mechanical strength (σb ≥650 MPa) and thermal cycling resistance.

- Airtight Sealing: Helium leakage rate <5×10⁻⁹ Pa·m³/s – critical for hermetic packaging in aerospace and military systems.

- Superior Functional Performance

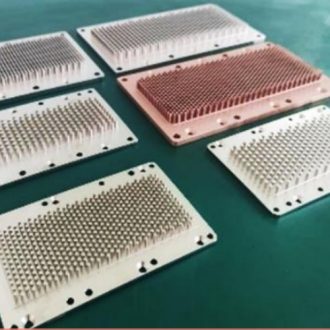

- Thermal Conductivity (180–220 W/m·K) : Rapid heat dissipation for high-power ICs and LED/LD microelectronic packaging.

- Low Thermal Expansion (6.5–8.5×10⁻⁶/°C) : Matches semiconductor CTE, minimizing thermal stress in devices.

- High-Temperature Stability: Maintains dimensional accuracy up to 800°C, ideal for EDM electrodes and welding tools.

Key Applications & FOTMA Solutions

| Industry | Critical Demands | FOTMA WCu Advantage |

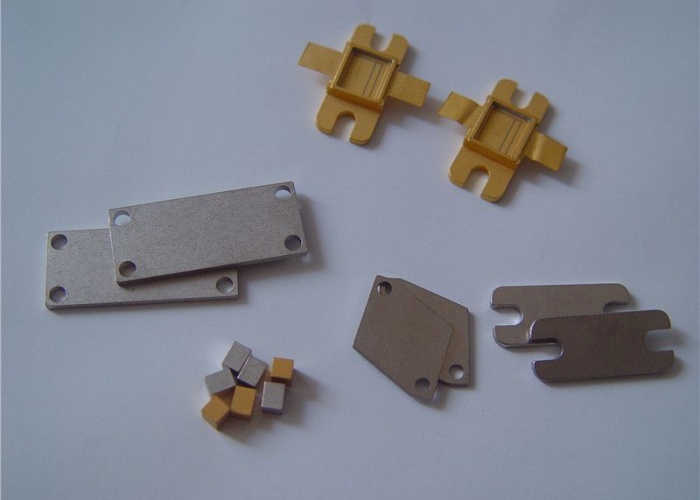

| Microelectronics | Thermal management in 5G/RF chips | Ultra-low porosity ensures leak-free encapsulation for GaN/SiC devices. |

| Resistance Welding | Electrode longevity in automotive lines | High conductivity (45–50% IACS) + wear resistance double lifespan vs. pure Cu. |

| EDM Tooling | Precision spark erosion in hard alloys | Fine-grained structure enables mirror EDM surfaces (Ra ≤0.1µm). |

| Military | Hypersonic vehicle “sweating” thermal shields | Customized WCu porosity achieves active cooling under 2000°C. |

| Industrial Molds | High-pressure die casting (Al/Mg) | High red hardness safeguards tool geometry for 100K+ cycles. |

Customization Capabilities

- Composition Flexibility: Adjust W/Cu ratios (50/50 to 90/10) for optimal conductivity vs. hardness.

- Complex Geometries: CNC-machined heatsinks, micro-channel cold plates, or thread-cooled electrodes.

- Surface Treatments: Optional Ni/Ag plating for oxidation resistance or laser texturing for enhanced heat transfer.

Quality Assurance

✅ Material Purity: W powder ≤0.5µm (99.99% purity), Cu-ETP grade.

✅ Defect-Free Guarantee: 100% X-ray inspection pre- and post-sintering.

✅ Global Compliance: RoHS, REACH, ITAR (for defense orders).

Why Choose FOTMA Copper Tungsten Material Heat Sink?

Replace Imports: Performance parity with global brands (Plansee, Sumitomo) at 20–30% lower cost.

Rapid Prototyping: Custom samples delivered in 10 days (standard sizes) via our in-house HIP facility.

Lifecycle Support: From thermal simulation to post-machining – FOTMA engineers ensure seamless integration.

FOTMA WCu Alloy – Where Precision Engineering Meets Unyielding Reliability.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074