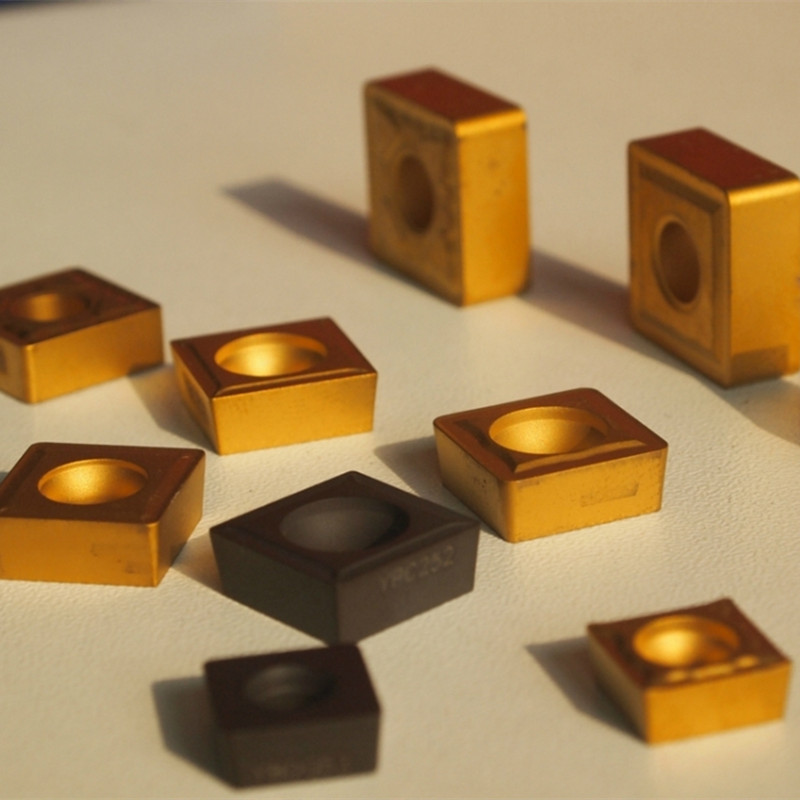

Tungsten Carbide Inserts

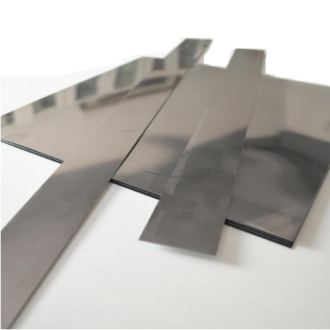

Material Grade for Tungsten Carbide Inserts:

|

Grade |

Applications |

| C2 Uncoated |

High wear resistance and high strength; machining chilled cast iron and refractory steel, finishing of normal cast iron. |

|

C5 Uncoated |

Excellent in strength, impact resistance and resistance to thermal shock ; Rough turning, rough planing and semi planing of Carbon steel and alloy steel. |

| ZK10UF |

Fine-grained alloy, good wear resistance and high strength. Semi-finishing and finishing of cast iron and nonferrous metals. It is the unique material for making of solid carbide tools for holing. |

|

ZK30UF |

Fine grain grade. Excellent wear resistance, high in strength and impact resistance. Machining of cast irons, nonferrous metals and non-metallic materials. It is the unique material of solid carbide tools for holing. |

In the field of modern precision machining, CNC inserts are the core element that determines machining efficiency, accuracy and stability. FOTMA cemented carbide inserts are a combination of cutting-edge material technology and precision manufacturing processes, designed to provide breakthrough cutting solutions for high-end manufacturing areas such as aerospace, mold and die manufacturing, medical devices, automotive industry and 3C electronics. Our superior material performance and customized machining capabilities help our customers gain a leading edge in demanding machining challenges.

Why Choose FOTMA Carbide Inserts

Faster cutting speed: aluminum alloy, titanium alloy, hardened steel …… all kinds of materials, we have a faster recommended cutting speed, efficiency enhancement can be seen!

Higher machining accuracy: Edge runout accuracy is controlled within 0.005mm, ensuring consistency of part dimensions, better surface finish, and reduced post-processing costs.

More durable life: Thermal crack resistance of more than 20,000 times, continuous intermittent cutting performance is excellent, the frequency of tool change is greatly reduced, saving time and cost.

More reliable quality: Strictly control the porosity and impurity content of inserts, each batch of inserts undergoes strict testing to ensure stable quality.

Material Grade for Carbide Inserts:

| Grade | Applications |

| C2 Uncoated | High wear resistance and high strength; machining chilled cast iron and refractory steel, finishing of normal cast iron. |

| C5 Uncoated | Excellent in strength, impact resistance and resistance to thermal shock ; Rough turning, rough planing and semi planing of Carbon steel and alloy steel. |

| ZK10UF | Fine-grained alloy, good wear resistance and high strength. Semi-finishing and finishing of cast iron and nonferrous metals. It is the unique material for making of solid carbide tools for holing. |

| ZK30UF | Fine grain grade. Excellent wear resistance, high in strength and impact resistance. Machining of cast irons, nonferrous metals and non-metallic materials. It is the unique material of solid carbide tools for holing. |

| ZP25 | Fine in wear resistance and toughness; Rough turning, milling, planing and depth drilling of carbon steel, cast steel, manganese steel and alloy steel. |

| ZP35 | A versatile grade, high in red hardness, strength and resistance to impact and thermal shocking. Roughing and strong cutting of steel and cast steel. |

| Suggestion: We would like to recommend suitable grade depending on your machining materials. | |

Value-added services from FOTMA make you save more!

Free cutting program consulting: provide professional carbide cutter inserts selection and cutting parameter suggestions to solve your machining problems.

Customized tool design: according to your special needs, tailor-made non-standard tools to meet individual processing needs.

Fast delivery service: standard inserts are available in stock, and customized inserts have a short delivery cycle without delaying the production schedule.

Perfect after-sales support: professional after-sales team, timely response to your questions, provide technical support and solutions.

CONTACT US NOW to get latest carbide insert price!

LATEST RECOMMENDED

Related products

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074