Tungsten Alloy Counterweights

Compared with other weight materials, the advantages of high density tungsten alloy weight are obvious:

|

Characteristic |

Tungsten Heavy Alloy Weight |

Traditional Counterweight Material |

|

Density |

Very high (17-18.5 g/cm³) |

Lower (steel approx. 7.8 g/cm³, lead approx. 11.3 g/cm³) |

|

Volume |

Smaller volume for the same weight, space saving |

Larger volume for the same weight, takes up more space |

|

Environmentally Friendly |

Non-toxic and harmless, in line with environmental requirements |

Lead is toxic and not good for the environment |

|

Strength & Hardness |

High, not easy to deform, wear-resistant |

Relatively low, easy to deform |

|

Machine ability |

Good, can be precision machined to meet the needs of complex shapes | Relatively poor, difficult to process precisely |

| Corrosion Resistance | Excellent, can work stably in a variety of environments |

Steel is easy to rust, lead is easy to oxidize |

|

Application |

Suitable for precision fields with strict requirements on volume and weight. |

Suitable for applications with low volume requirements and cost sensitivity |

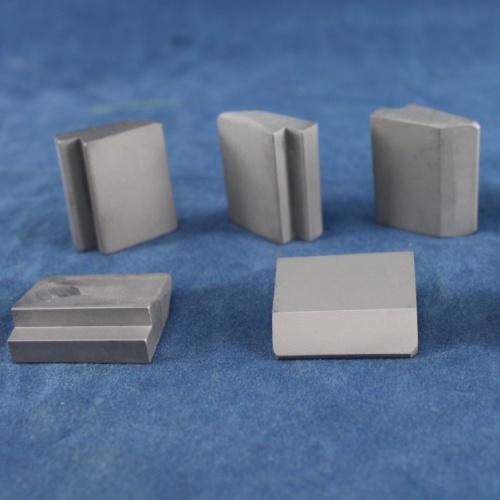

High Density Tungsten Alloy Counterweights: Small In Size, Big In Power, Great In Balance.

In modern industry and technology, balance is crucial. Whether it is a high-speed rotating impeller or a robotic arm that requires precise positioning, a reliable counterweight is the key to ensuring stable and efficient operation. FOTMA’s superior tungsten material processing technology provides you with high-performance, high-density tungsten counterweight solutions that help you achieve more precise and reliable balance control with their small size and high weight.

High density tungsten alloy counterweight, as the name suggests, is a counterweight component made of high density tungsten alloy material. Tungsten alloy, an alloy of tungsten matrix and other metal elements such as nickel, copper, iron, etc., has an amazingly high density (typically 17-18.5 g/cm³), which is several times higher than that of traditional counterweight materials. This makes tungsten alloy counterweights smaller in size under the same weight, and can adapt to more space limited application scenarios.

Applications of High Density Tungsten Alloy Counterweights:

Aerospace field: used for balancing wings, counterweights, dynamic balancing components, etc. in aircraft, missiles, and satellites to improve flight stability and control accuracy, optimize center of gravity distribution.

– Automotive industry: used in engine crankshafts, flywheels, wheel hubs and other parts of the balance block, reduce vibration, improve driving smoothness and safety.

Mechanical manufacturing industry: As a dynamic balance weight for machine tool spindles, high-speed rotating equipment, and precision instruments, it reduces noise, extends equipment life, and improves machining accuracy.

– Sports equipment industry: Used in the weight block of golf club head, fishing rod, dart and other products to optimize the center of gravity and improve sports performance.

Medical device industry: used for balancing arms in medical imaging equipment, as well as other medical devices that require precise balancing.

– Oil and gas industry: as weighted rods for drilling tools to increase drilling pressure and improve efficiency.

– Other industrial applications: e.g. robots, automation equipment, measuring instruments, etc. where precise weight balancing is required.

Why Choose FOTMA tungsten alloy weights:

Excellent material quality: Made with high-purity tungsten powder and advanced powder metallurgy technology, ensuring uniform weight density and stable performance.

Precision machining technology: With advanced CNC machining equipment and experienced technical team, we can carry out precision machining according to customers’ drawings and requirements to meet various complex shapes and high precision requirements.

Flexible customization service: We can provide customized tungsten alloy counterweights in different sizes, shapes, weights, and alloy compositions according to the actual needs of customers.

Strict quality control: From raw materials to finished products, each step of the process is strictly inspected to ensure that the products meet the standards.

Professional solutions: Our engineering team can provide you with professional counterweight design and technical support to help you solve balance problems.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074