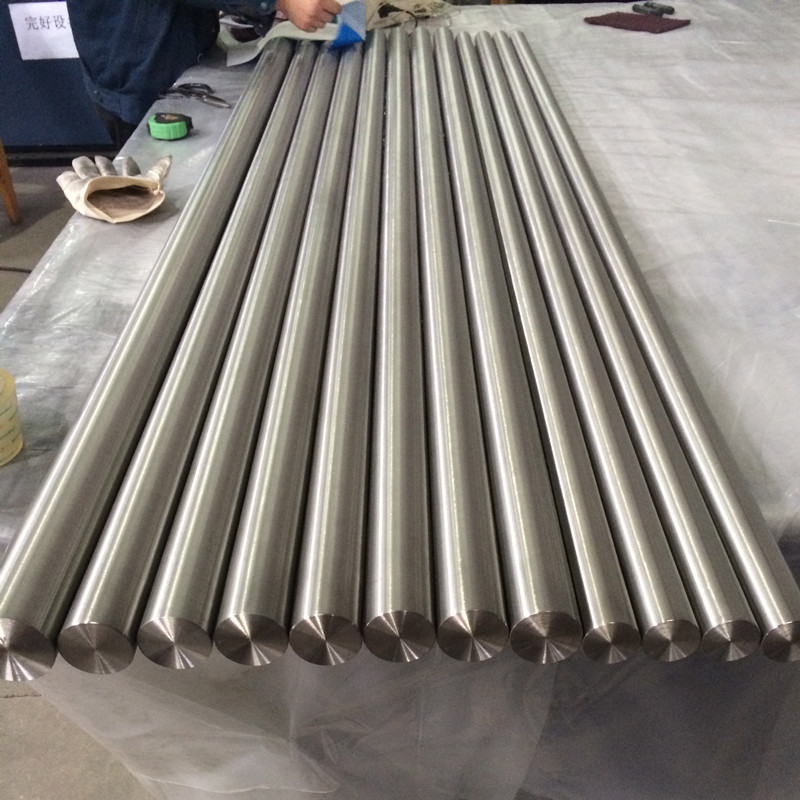

Titanium Rod

Titanium Round Bar Specifications:

- Material Grades:

- Pure Titanium: Gr1, Gr2, Gr3, Gr4 (Complies with ASTM B348)

- Titanium Alloys: Gr5 (Ti-6Al-4V), Gr7, Gr9 (Ti-3Al-2.5V), Gr12, Gr23 (Ti-6Al-4V ELI), etc. (Complies with ASTM B348) or other custom alloys

- Diameter: 6mm to 300mm or larger diameters, customizable

- Length: Available in various lengths according to customer requirements.

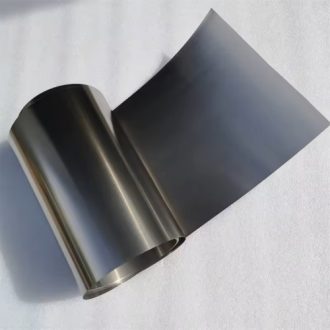

- Surface Finish: Smooth, turned, ground, polished, pickled, customizable

- Tolerance: Available in precision tolerances as per customer requirements

- Processing Methods: Hot-rolled, cold-drawn, forged, etc.

FOTMA High-Performance Titanium Rod/Titanium Round Bar: Superior Characteristics, Your Choice for Quality

FOTMA is dedicated to producing high-quality titanium rods and bars, showcasing unparalleled application value in various fields due to their exceptional product characteristics. We strictly control every aspect of the production process, selecting premium titanium raw materials and employing advanced processing techniques to ensure each titanium rod possesses superior performance, meeting your stringent material requirements. Choose FOTMA and you’ll receive high-performing, quality-stable titanium bar products, laying a solid foundation for the success of your projects.

Characteristics of Pure Titanium Rod Material:

- Unmatched Strength-to-Weight Ratio: Titanium bars possess extremely high strength while being lightweight, making them uniquely advantageous in aerospace, automotive light weighting, and other fields. They can reduce structural weight while ensuring material strength and reliability.

- Exceptional Corrosion Resistance: Titanium bars exhibit excellent corrosion resistance in various corrosive environments. Whether in seawater, chloride solutions, or acidic/alkaline media, titanium bars maintain their stability, effectively extending product lifespan and reducing maintenance costs.

- Excellent Biocompatibility: Titanium is an ideal medical material, non-toxic and harmless to human tissues, with outstanding biocompatibility. It is widely used in medical implants and surgical instruments, ensuring patient safety and health.

- Outstanding High-Temperature Resistance: Titanium bars maintain good mechanical properties at high temperatures, with exceptional creep resistance, making them suitable for high-temperature applications such as aircraft engines and high-temperature components, ensuring stable equipment operation under extreme conditions.

- Good Low-Temperature Performance: Certain titanium alloys maintain good ductility and toughness at low temperatures, suitable for cryogenic engineering and low-temperature equipment, ensuring structural safety at extreme temperatures.

- Non-Magnetic: Titanium is a non-magnetic material, unaffected by magnetic fields, suitable for use in precision instruments and medical devices to avoid magnetic interference and ensure normal equipment operation.

- Low Modulus of Elasticity: Compared to steel, titanium alloys have a lower modulus of elasticity, closer to that of human bone, making them better suited for orthopedic implant applications to reduce stress concentration and bone remodeling.

- Good Machinability: FOTMA’s titanium bars undergo precision processing, possessing good machinability, making them easy to turn, mill, and drill for secondary processing and convenient for manufacturing.

- Diverse Selection: FOTMA offers various specifications, grades, and sizes of titanium bars, including pure titanium bars and titanium alloy bars with different compositions, meeting the specific needs of different application fields.

- Precise Dimensional Control: FOTMA employs advanced processing and testing technologies to ensure that every titanium bar has precise dimensional tolerances and surface finish, reducing secondary processing losses and improving product quality.

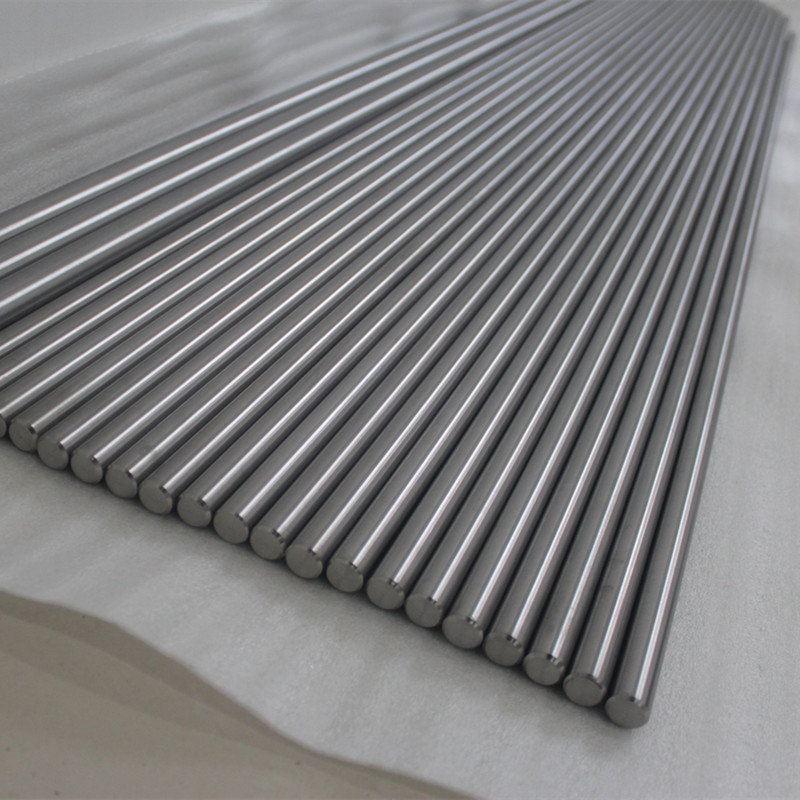

Titanium Alloy Bar Specifications:

- Material Grades:

- Pure Titanium: Gr1, Gr2, Gr3, Gr4 (Complies with ASTM B348)

- Titanium Alloys: Gr5 (Ti-6Al-4V), Gr7, Gr9 (Ti-3Al-2.5V), Gr12, Gr23 (Ti-6Al-4V ELI), etc. (Complies with ASTM B348) or other custom alloys

- Diameter: 6mm to 300mm or larger diameters, customizable

- Length: Available in various lengths according to customer requirements.

- Surface Finish: Smooth, turned, ground, polished, pickled, customizable

- Tolerance: Available in precision tolerances as per customer requirements

- Processing Methods: Hot-rolled, cold-drawn, forged, etc.

Applications of Titanium Alloy Rod:

- Aerospace: Aircraft structural components, engine parts, fasteners

- Medical Devices: Orthopedic implants, dental implants, surgical instruments

- Chemical Industry: Corrosion-resistant pipes, reactors, heat exchangers

- Marine Engineering: Subsea pipelines, marine platforms, desalination equipment

- Automotive Industry: Engine parts, exhaust systems, suspension systems

- Sporting Goods: Golf club heads, bicycle frames, skis

- Other Industrial Applications: Variety of structural parts, connecting parts, etc.

Why Choose Us:

- High-Quality Assurance: Selected high-quality titanium raw materials, ensuring stable and reliable product performance.

- Advanced Production Processes: Employing precision machining and testing technologies to ensure dimensional accuracy and surface quality.

- Strict Quality Control: ISO 9001 certified quality management system, ensuring products meet international standards.

- Professional Technical Support: Experienced engineering team providing material selection and technical consulting services.

- Customized Services: Providing titanium bars in various specifications and grades according to customer requirements.

- Fast and Flexible Response: Quick quote and delivery, meeting urgent customer needs.

CONTACT US NOW TO GET LATEST TITANIUM ROD PRICE!

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074