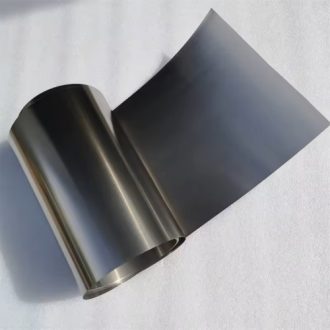

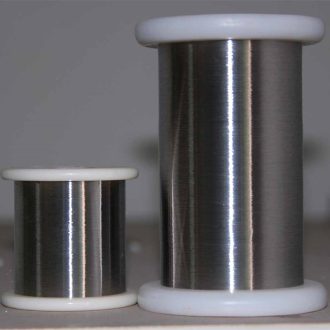

Titanium Alloy Products

Lightweight & High Strength: With a density of 4.51 g/cm³ (only 57% of steel) yet comparable strength to high-grade steel, titanium is the premier choice for lightweight solutions in aerospace and precision equipment.

Unrivaled Corrosion Resistance: A naturally formed oxide layer grants titanium outstanding resistance to seawater, chlorides, strong acids/alkalis, and high-temperature oxidation, ensuring decades of service life.

Biocompatible Material: Non-toxic and fully compatible with human tissue, certified under ISO 13485 medical standards, making it ideal for implants and surgical instruments.

Custom Titanium Products – Engineered for Your Demanding Applications

Titanium and titanium alloy products, recognized as one of the most valuable engineering metals of the 20th century, is renowned for its high strength-to-weight ratio, exceptional corrosion resistance, and superior biocompatibility.

- Lightweight & High Strength: With a density of 4.51 g/cm³ (only 57% of steel) yet comparable strength to high-grade steel, titanium is the premier choice for lightweight solutions in aerospace and precision equipment.

- Unrivaled Corrosion Resistance: A naturally formed oxide layer grants titanium outstanding resistance to seawater, chlorides, strong acids/alkalis, and high-temperature oxidation, ensuring decades of service life.

- Biocompatible Material: Non-toxic and fully compatible with human tissue, certified under ISO 13485 medical standards, making it ideal for implants and surgical instruments.

Advantages of Titanium Material

✔ Superior Performance

- High Strength & Lightweight: Titanium alloys exceed steel in strength while being 60% lighter, enabling significant weight reduction and efficiency gains.

- Extreme Environment Durability: Resists corrosion (seawater, acids/alkalis, oxidation), stable across wide temperature ranges (-253°C to 600°C).

✔ Tailored Flexibility

- Custom Design: Supports complex geometries, tight tolerances (±0.05mm), and specialized functions (porous structures, surface coatings).

- End-to-End Solutions: Full-service capabilities including material selection (CP Ti/TC4/TC11), process optimization (casting/forging/3D printing), and post-processing (heat treatment/polishing).

Applications of Titanium Parts:

- Industrial Manufacturing: Aerospace components, marine engineering systems, chemical reactors.

- Medical Technology: Orthopedic implants, surgical tools, dental prosthetics.

- Advanced Technologies: Critical semiconductor equipment parts, superconducting material substrates.

Our Commitments

- Precision Delivery: 20+ years of titanium expertise, proven by 100+ successful projects, with a 99% on-time completion rate.

- Rigorous Quality Control: ISO 9001 certified, full-process traceability, guaranteed compliance with mechanical and chemical standards.

- Rapid Response: 48-hour technical feedback, prototyping and small-batch production support.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074