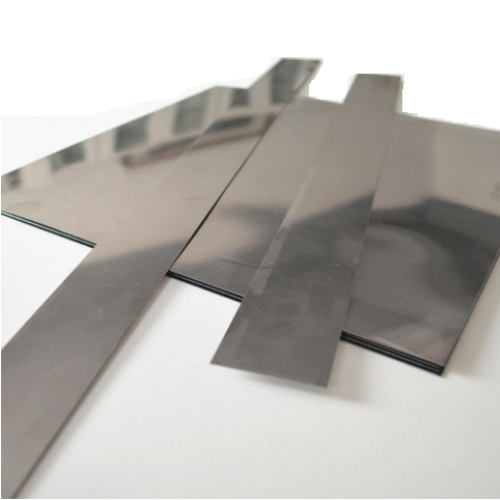

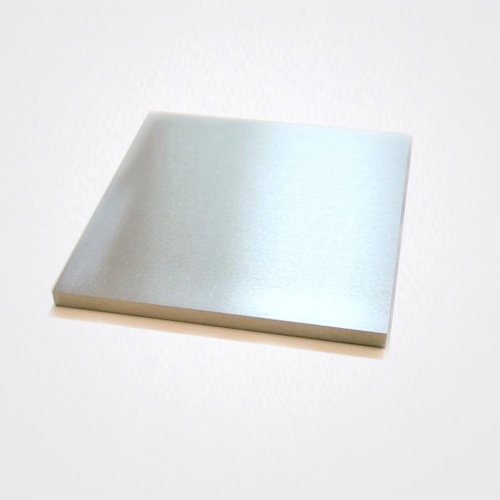

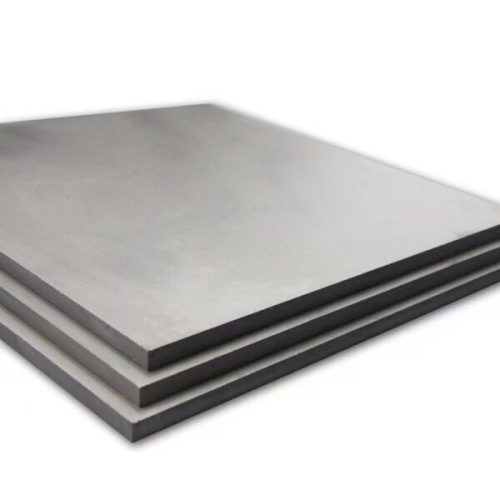

Tantalum Sheet

|

Details |

|

|

Material Grades |

Pure Ta (Ta1, Ta2) / Ta Alloys (Ta2.5W, Ta10W) |

|

Thickness |

0.01 mm – 10 mm |

|

Width |

Up to 1500 mm |

| Length |

Customizable (max. 6000 mm) |

|

Surface Finish |

Polished (Ra ≤0.8 µm), Anodized, or Coated |

Tantalum sheets and foils, as critical forms of tantalum metal, leverage the material’s exceptional properties to serve vital roles in advanced industrial applications. Below is a detailed overview of their features and specifications.

Material Properties:

- Corrosion Resistance: Resistant to strong acids (hydrochloric, sulfuric, nitric), alkalis, and high-temperature chlorides in both ambient and elevated temperature environments.

- High Melting Point: Melting point of 3017°C, retaining structural integrity and mechanical performance under extreme heat.

- Biocompatibility: Compliant with ISO 10993 standards, suitable for medical implants and devices.

- Electrical Conductivity: Excellent conductivity, ideal for electronic and electrical components.

Applications:

- Chemical Industry: Liners, reactor components, and corrosion-resistant piping.

- Electronics: Electrodes for high-performance capacitors, connectors and switches

- Aerospace: Heat-resistant shielding and insulation.

- Medical: Orthopedic implants, vascular stents, and surgical tools.

Tantalum Sheet Specifications:

| Details | |

| Material Grades | Pure Ta (Ta1, Ta2) / Ta Alloys (Ta2.5W, Ta10W) |

| Thickness | 0.01 mm – 10 mm |

| Width | Up to 1500 mm |

| Length | Customizable (max. 6000 mm) |

| Surface Finish | Polished (Ra ≤0.8 µm), Anodized, or Coated |

| Density | 16.6 g/cm³ (pure Ta) |

| Melting Point | 3017°C |

| Electrical Conductivity | ~40% IACS |

| Mechanical Properties | Tensile Strength ≥500 MPa / Elastic Modulus: 110 GPa |

| Length | Customizable (max. 6000 mm) |

| Surface Finish | Polished (Ra ≤0.8 µm), Anodized, or Coated |

| Electrical Conductivity | ~40% IACS |

| Thermal Stability | Long-term stability at 1600°C in vacuum |

How to Select the Right Material Grade?

- Environmental Compatibility: Match material grade to chemical exposure (acid/alkali concentration, temperature).

- Thermal Requirements: Opt for Ta-W alloys (e.g., Ta10W) for high-temperature strength and creep resistance.

- Dimensional Precision: Specify thickness, width, and tolerance (±0.02 mm achievable).

- Surface Treatment: Choose polishing, anodization, or coatings to enhance performance.

Tantalum sheets and foils offer unparalleled performance in demanding applications across industries like chemical processing, aerospace, electronics, and healthcare. Let our precision-engineered solutions redefine the limits of your technology.

LATEST RECOMMENDED

Related products

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074