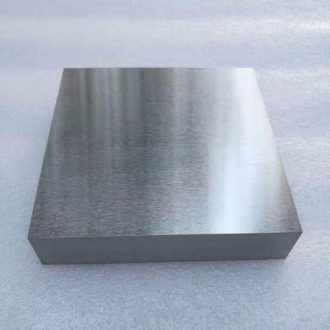

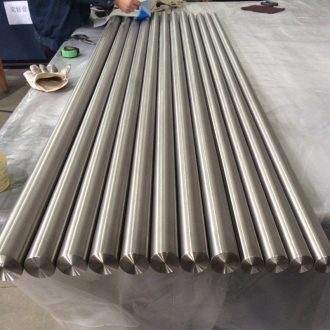

Tantalum Rods Tantalum Bars

|

Parameter |

Details |

|

Material Grades |

– Pure Tantalum: Ta1 (ASTM B365 R05200), Ta2 (R05400) |

|

– Tantalum Alloys: Ta2.5W (R05255), Ta10W (R05252) |

|

|

Dimensions |

– Diameter: 5mm–150mm (±0.02mm) |

|

– Length: Up to 6,000mm (customizable) |

|

| Density |

16.6 g/cm³ (pure Ta) |

Tantalum Rods Tantalum Bars – Reliable Solutions for Extreme Environments

Material Overview

Tantalum, hailed as the “King of Corrosion Resistance,” is a strategic metal for advanced industries and high-tech applications, renowned for its unrivaled corrosion resistance, ultra-high melting point, exceptional biocompatibility, and unique electrical properties:

- Ultimate Corrosion Resistance: Nearly inert at ambient temperatures, resistant to concentrated hydrochloric acid (37%), sulfuric acid (98%), nitric acid, and other aggressive media. Outperforms titanium and platinum, making it the optimal choice for chemical and medical equipment.

- High-Temperature Performance: Melting point of 3017°C, retaining strength and oxidation resistance under extreme heat. Ideal for vacuum furnaces and aerospace engine components.

- Medical-Grade Safety: Compliant with ISO 10993 biocompatibility standards, non-toxic and hypoallergenic, widely used in orthopedic implants and minimally invasive surgical tools.

- Superior Electrical Properties: High dielectric constant and stability, critical for high-end capacitor manufacturing.

Advantages

✔ Unmatched Resistance to Extreme Environments

- Chemical Inertness: Stable in strong acids (HCl, H2SO4, HNO3), molten alkalis, and high-temperature chlorides, with zero risk of crevice corrosion.

- High-Temperature Resilience: Zero oxidation below 1200°C, long-term usability in 1600°C vacuum environments.

✔ Advanced Customization Capabilities

- Precision Dimensions: Diameter 5mm to 150mm, custom lengths (up to 6 meters), tolerances as tight as ±0.02mm.

- Versatile Processing: Forged rods (high density), rolled rods (smooth surface finish), and surface treatments (anodizing/polishing/coatings).

- Material Options: Pure tantalum rods (Ta1, Ta2), tantalum-tungsten alloys (Ta2.5W, Ta10W), tailored for varying strength and temperature requirements.

Key Applications

- Chemical & Energy: Liners for acid reactors, nuclear fuel cladding tubes, electrolysis anodes.

- Medical & Life Sciences: Cranial reconstruction plates, vascular stents, endoscope components.

- Electronics & Semiconductor: High-performance capacitor sputtering targets, semiconductor etching rings.

- Aerospace: Rocket nozzle components, satellite thermal protection substrates.

Product Specifications

| Parameter | Details |

| Material Grades | – Pure Tantalum: Ta1 (ASTM B365 R05200), Ta2 (R05400) |

| – Tantalum Alloys: Ta2.5W (R05255), Ta10W (R05252) | |

| Dimensions | – Diameter: 5mm–150mm (±0.02mm) |

| – Length: Up to 6,000mm (customizable) | |

| Density | 16.6 g/cm³ (pure Ta) |

| Melting Point | 3017°C |

| Surface Finish | – Rolled: Ra ≤0.8µm |

| – Forged: Ra ≤1.6µm | |

| Tolerances | – Diameter: ±0.02mm (standard), tighter options available |

| – Straightness: ≤0.1mm per meter | |

| Certifications | ISO 10993 (Biocompatibility), ASTM B365, RoHS/REACH compliant |

| Testing Standards | – Oxygen content: ≤500 ppm (pure Ta) |

| – Grain size: ASTM E112 | |

| – Hardness: HV tested per ASTM E384 |

Key Applications

- Chemical & Energy: Liners for acid reactors, nuclear fuel cladding tubes, electrolysis anodes.

- Medical & Life Sciences: Cranial reconstruction plates, vascular stents, endoscope components.

- Electronics & Semiconductor: High-performance capacitor sputtering targets, semiconductor etching rings.

- Aerospace: Rocket nozzle components, satellite thermal protection substrates.

Our Commitments

- End-to-End Traceability: Full transparency from raw tantalum ore to finished rods, compliant with ASTM B365 standards.

- Rigorous Quality Assurance: Dual-inspected for grain size, oxygen content, hardness, and batch consistency.

- Fast Turnaround: Prototypes in 7 days, small-to-medium batch delivery within 15 days (emergency non-standard orders supported).

LATEST RECOMMENDED

Related products

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074