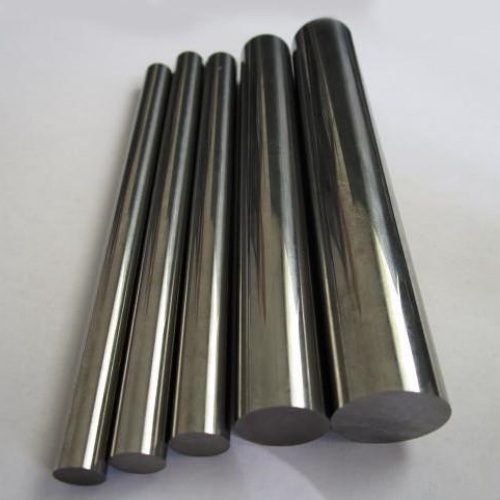

Pure Tungsten Rod

| Dimension and Tolerance of Pure Tungsten Rods | |||

| Diameter | Diameter Tolerance | Max Length | |

| Polished surface | Black/Alkaline cleaning surface |

||

| <10 | ±0.05 | ±0.05 or ±0.2 | 2500 |

| 10-30 | ±0.05 | ±0.05 or ±0.2 | 2000 |

| 30-60 | ±0.05 | ±0.05 or ±0.2 | 1500 |

| 60-100 | ±0.05 | ±0.05 or ±0.2 | 1000 |

| 100-200 | ±0.05 | ±0.05 or ±0.2 | 600 |

| >200 | ±0.05 | ±0.05 or ±0.2 | Customized |

Pure Tungsten Rod

Pure tungsten rods have special properties such as high density, high melting point, small size, extremely high wear resistance, extremely high hardness, high tensile strength, high elongation, and high temperature resistance. Therefore, tungsten rods are widely used in various fields. Such as support wires, guiding wires, printer needles, various electrodes and quartz furnaces, filaments, high-speed tools, automotive automation products, sputtering targets etc.

Pure tungsten rods have multiple uses, mainly including the following aspects:

Thermodynamics field:

Electrode: Pure tungsten rod is an ideal material for manufacturing high-strength electrodes, which can be used as electrodes for equipment such as arc welding, argon arc welding, plasma cutting, and electron beam welding. Due to its high melting point and stable arc characteristics, pure tungsten rods can work stably for a long time at high temperatures.

High temperature furnace: Pure tungsten rods have excellent heat resistance at high temperatures and are widely used as heating elements in high-temperature furnaces. Will not melt or deform at high temperatures, ensuring long-term stable operation of the equipment

Electrical field:

Electrode: Pure tungsten rods are used to manufacture various types of electrodes, such as electronic tubes, capacitors, arc bulbs, and high-voltage tubes, due to their excellent conductivity, stability, and high-temperature performance

Electric heater: Pure tungsten rods have excellent resistance heating characteristics and are widely used as heating elements in electric heaters. No plastic deformation occurs at high temperatures, ensuring the stability and service life of the equipment

In the field of chemistry:

Chemical reactor: Pure tungsten rods can be used to manufacture heating elements for chemical reactors due to their excellent corrosion resistance and high-temperature performance, which can work stably for a long time in extreme chemical environments and high temperatures

Stabilizer: Pure tungsten rods can be used to manufacture tungstate stabilizers, which play a stabilizing role in chemical reactions and can work stably for a long time in harsh chemical environments

Mechanical field:

Cutting tools: Pure tungsten rods can be used as materials for manufacturing high-speed steel, hard alloys, and ceramic cutting tools. Its high hardness and wear resistance make it suitable for high-quality, high-precision cutting tools

Hard alloy: Pure tungsten rod is an important raw material for manufacturing hard alloys, which can improve the hardness and wear resistance of hard alloys, ensure their long-term stability and service life

Other uses:

Resistance welding machine electrode: Pure tungsten rod is also used for resistance welding machine electrode

Sputtering targets, counterweights, and heating elements, etc

Tungsten rod Surface Finish

Black – Surface is “as swaged” or “as drawn”; retaining a coating of processing lubricants and oxides.

Cleaned – Surface is chemically cleaned to remove all lubricants and oxides.

Ground – Surface is centerless ground to remove all coating and to achieve precise diameter control.

Tungsten content: 99.95%

Size: 5.0mm~100mm diameter, tungsten rod 3mm

Surface: Sintering surface, Forged surface, Ground surface

Length: 50-1000mm

CHECK WITH US FOR TUNGSTEN ROD STOCK NOW!

Dimension and Tolerance

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074