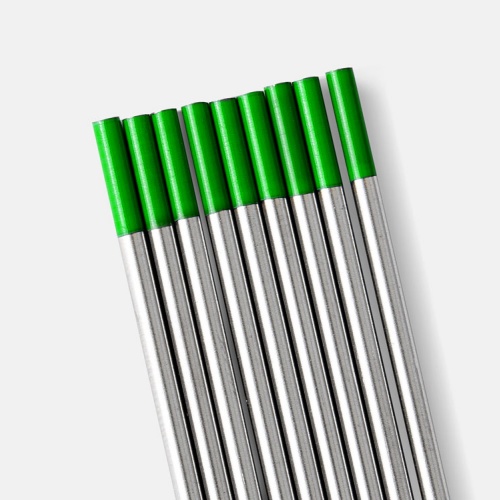

WP Pure Tungsten Electrode

|

Diameter (mm) |

Recommended Current (A) | Typical Applications |

| 1.0–1.6 | 50–100 |

Thin sheet welding (<3mm), fine repairs |

|

2.4–3.2 |

150–250 | Medium-thick plates, pipe joints |

| 4.0–6.4 | 300–400 |

Heavy-duty welding, high-load operations |

Pure Tungsten Electrodes for TIG Welding: Core Material for High-Performance Arc Welding

Pure tungsten electrodes, composed of >99.95% high-purity tungsten, are critical components in TIG (Tungsten Inert Gas) welding processes. Designed for scenarios requiring stable arcs and high-temperature inert environments, they deliver exceptional resistance to heat and corrosion, making them ideal for AC welding of materials like aluminum and magnesium alloys.

Core Applications of Pure Tungsten Rods for TIG Welding

- Aluminum Alloy Welding:

- In AC TIG welding of aluminum, magnesium, and their alloys, pure tungsten electrodes leverage the cathodic cleaning effect to remove surface oxides, ensuring high-quality welds.

- Precision Welding:

- Suitable for thin sheets, high-accuracy components (e.g., aerospace parts, nuclear reactor vessels), and contamination-sensitive applications.

- Harsh Environment Welding:

- Stable performance in high-temperature, corrosive conditions (e.g., chemical equipment maintenance), resisting spatter and gas erosion.

Key Performance Advantages

- Ultra-High Melting Point and Thermal Stability:

- With a melting point of 3,422°C, pure tungsten retains structural integrity under prolonged high-temperature arc exposure.

- Superior Arc Stability:

- Focused, drift-free arcs in AC welding, ideal for continuous operations (e.g., automated production lines).

- Eco-Friendly and Safe:

- Zero radioactivity (vs. thoriated electrodes), compliant with EU RoHS standards, ensuring safety for users and environments.

- Adjustable Current Capacity:

- Available in diameters 1.0–6.4mm, supporting current ranges of 50–400A (adjustable based on diameter and cooling conditions).

| Diameter (mm) | Recommended Current (A) | Typical Applications |

| 1.0–1.6 | 50–100 | Thin sheet welding (<3mm), fine repairs |

| 2.4–3.2 | 150–250 | Medium-thick plates, pipe joints |

| 4.0–6.4 | 300–400 | Heavy-duty welding, high-load operations |

Material Science and Manufacturing

- Purity Control:

Raw materials undergo powder metallurgy refinement to ensure >99.95% tungsten purity, with impurities (Fe, Mo, etc.) <0.03% , minimizing weld spatter. - Precision Forming:

Rotary forging or drawing processes create straight electrodes; tips are ground to a 15°–30° taper angle for optimized arc focus. - Surface Treatment:

Polished or oxide-coated variants reduce arc ignition difficulty and extend service life.

Comparison with Other Electrodes

| Property | Pure Tungsten | Thoriated (2% ThO₂) | Ceriated (2% CeO₂) |

| Radioactivity | None | Low-level thorium (requires special handling) | None |

| AC Welding Performance | Optimal arc stability | Requires high-frequency ignition; noisy arcs | Moderate performance |

| DC Welding Suitability | Poor (weak electron emission) | Excellent (easy ignition, heat-resistant) | Good |

| Typical Use Cases | Aluminum AC TIG welding | Stainless steel DC welding | General-purpose (mild steel, titanium) |

Usage and Maintenance Guidelines

- Grinding Specifications:

- Use dedicated tungsten grinders to ensure symmetrical tips, preventing arc deviation from eccentricity.

- Gas Shielding:

- Pair with 100% argon or argon-helium mix; flow rate 10–20 L/min for oxidation-free weld pools.

- Current Limits:

- Avoid exceeding recommended currents (based on diameter) to prevent tip melting or weld contamination.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074