Nickel Alloy Wires

|

Parameter |

Details |

|

Material Grades |

Nickel 200/201, Inconel 600/601, Monel 400, Hastelloy C276, Nitinol (Ni-Ti alloy) |

|

Diameter Tolerance |

±0.001 mm (ultra-precision grade), ±0.01 mm (standard grade) |

|

Tensile |

300 MPa – 1600 MPa (customizable via heat treatment) |

| Wire Forms |

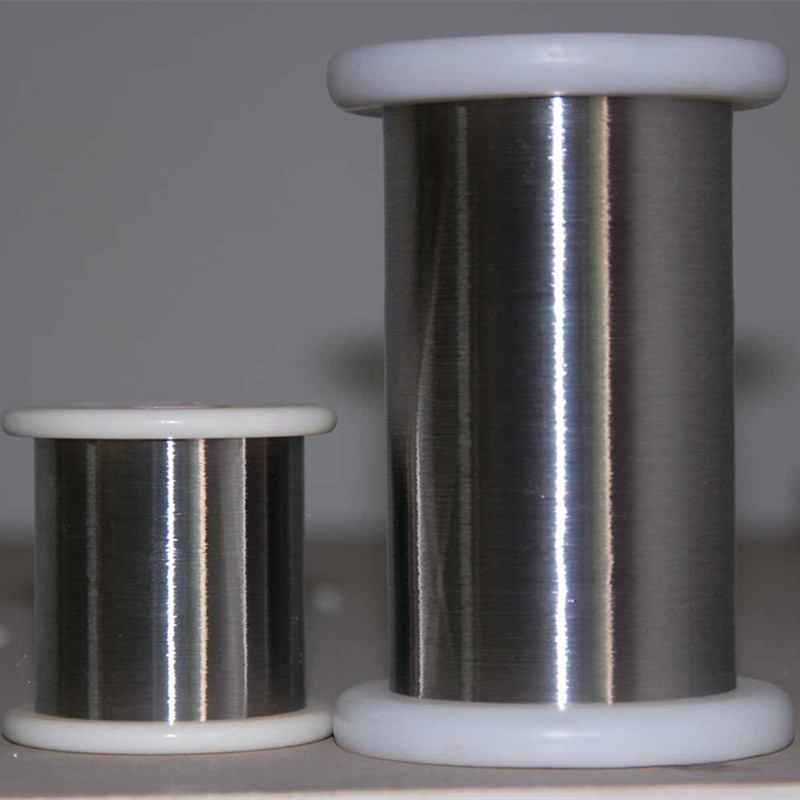

Straight wires, coils (1 kg – 500 kg), pre-straightened/cut lengths |

FOTMA Premium Nickel Alloy Wires: Where Precision Meets Durability

FOTMA nickel alloy wires stand out as critical materials for high-temperature, corrosive, and high-stress environments, thanks to their exceptional performance and precision engineering. Designed for advanced industries such as electronics, medical devices, and aerospace, our wires combine superior conductivity, fatigue resistance, and stability in extreme conditions, making them the ideal choice for delicate component manufacturing.

Product Features:

- Ultra-Fine Diameter & High Surface Precision

- Diameter range: 0.01 mm – 5.0 mm (custom ultra-fine sizes available).

- Surface roughness: Ra ≤ 0.2 µm (mirror polishing optional), meeting requirements for high-sensitivity components like micro-sensors and precision coils.

- Elastic-Plastic Dual Advantage

- High elastic modulus (≥190 GPa) paired with ductility (20%-40% elongation), ideal for springs, connectors, and applications requiring repeated deformation.

- Stable Conductivity & Low Resistivity

- Resistivity as low as 0.096 µΩ·m (e.g., Nickel 200), enabling efficient energy transfer for battery tabs, electrical contacts, and more.

- Hydrogen Embrittlement & Radiation Resistance

- Special alloy formulations (e.g., Inconel® 600) resist hydrogen penetration and radiation damage, suitable for nuclear and hydrogen energy systems.

- Biocompatibility & Sterile Surfaces

- Medical-grade Ni-Ti alloy wires (e.g., Nitinol) comply with ISO 13485, used for cardiovascular stents, orthopedic guide wires, and implants.

Specifications:

|

Parameter |

Details |

| Material Grades |

Nickel 200/201, Inconel 600/601, Monel 400, Hastelloy C276, Nitinol (Ni-Ti alloy) |

|

Diameter Tolerance |

±0.001 mm (ultra-precision grade), ±0.01 mm (standard grade) |

|

Tensile |

300 MPa – 1600 MPa (customizable via heat treatment) |

| Wire Forms |

Straight wires, coils (1 kg – 500 kg), pre-straightened/cut lengths |

|

Special Coatings |

Gold/silver plating, PTFE coating (anti-corrosion/insulation) |

| Certifications |

ASTM F2063 (shape memory alloys), RoHS, REACH, NADCAP (aerospace) |

Innovative Applications:

- Microelectronics: Semiconductor wire bonding, high-density FPC flexible circuits.

- High-Temperature Sensors: Aircraft engine thermo-couples, industrial furnace probes.

- Biomedical: Biodegradable vascular stent wires, endoscopic guidewires.

- New Energy: Fuel cell bipolar plate conductive wires, hydrogen tank reinforcement fibers.

- Precision Manufacturing: 3D printing filaments, micro-motor rotor windings.

FOTMA Value-Added Services:

Deep Customization: Tailored alloy formulas based on resistivity, CTE, permeability, etc.

Performance Testing: Fatigue life tests, corrosion cycle tests, conductivity mapping reports.

Micro-Packaging Solutions: Anti-static/vacuum packaging, medical-grade sterile pouches.

Secondary Processing: Laser cutting, micro-welding, polishing, and one-stop machining.

Why FOTMA?

- Pure Materials: Electron beam melting (EBM) ensures impurity levels below 10 ppm.

- AI-Powered Inspection: Optical defect detection eliminates surface flaws with 100% screening.

- Rapid Delivery: Samples shipped within 24 hours; custom orders fulfilled in 7-15 days.

FOTMA Nickel Alloy Wires — Connecting future technologies with extreme precision!

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074