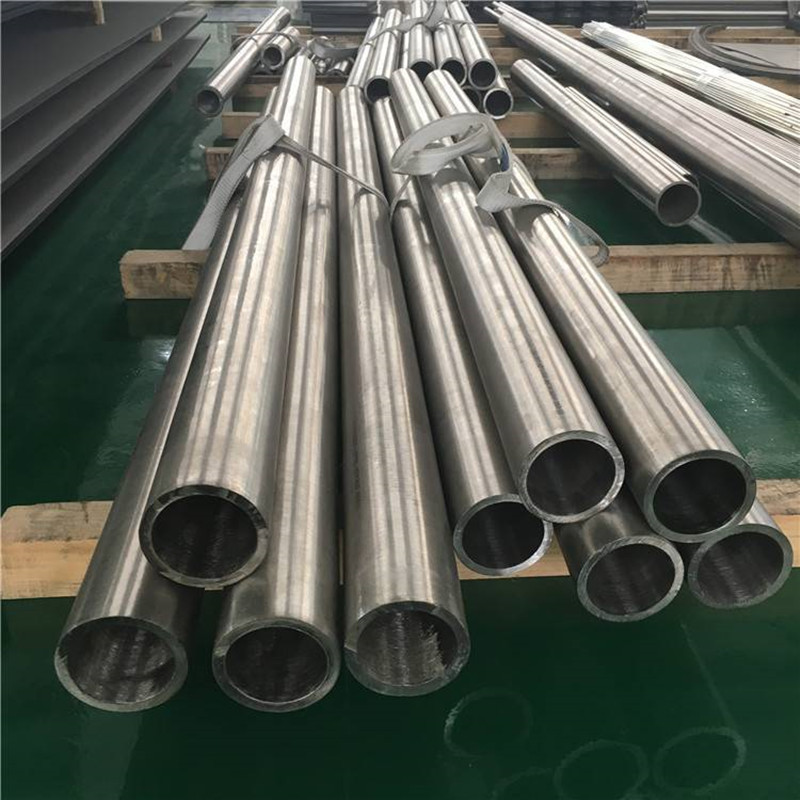

Nickel Alloy Tube / Nickel Pipe

|

Parameter |

Details |

| Grades |

Inconel 625, Hastelloy C276, Monel 400 |

|

Standard Sizes |

OD: 6–300 mm|WT: 0.5–25 mm|Length: ≤12 m |

| Standards |

ASTM B163/167/622, ASME SB163, DIN 17750 |

|

Surface Finish |

Polished, Pickled, Annealed, or Custom |

| Pressure Rating |

Up to 100 MPa (contingent on dimensions) |

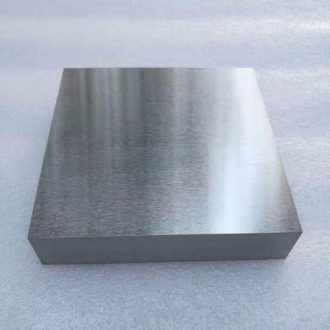

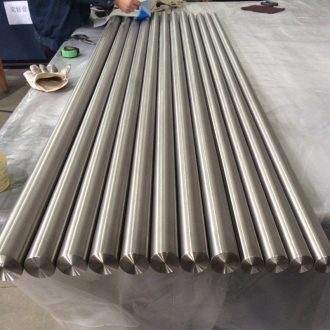

Nickel alloy tubes are precision-engineered solutions designed for extreme environments. Commonly used grades include Inconel 625 (UNS N06625), Hastelloy C276 (UNS N10276) , and Monel 400 (UNS N04400) , Copper Nickel Tube. These tubes combine outstanding corrosion resistance, high-temperature stability, and superior mechanical strength, making them critical for demanding applications in chemical processing, aerospace, oil & gas, and power generation.

Key Features

- Corrosion Resistance: Excellent resistance to acids (HCl, H₂SO₄), chlorides, and seawater, minimizing pitting and stress corrosion cracking.

- Thermal Performance: Operates continuously at 600–1100°C (depending on grade), with creep resistance under prolonged thermal stress.

- Mechanical Durability: High tensile strength (≥700 MPa) and toughness for high-pressure/vibration environments.

- Customization: Available in seamless/welded forms, OD 6–300 mm, wall thickness 0.5–25 mm, with cold-drawn or annealed finishes.

Technical Specifications

|

Parameter |

Details |

|

Grades |

Inconel 625, Hastelloy C276, Monel 400, copper nickel alloy tubing |

| Standard Sizes |

OD: 6–300 mm|WT: 0.5–25 mm|Length: ≤12 m |

|

Standards |

ASTM B163/167/622, ASME SB163, DIN 17750 |

| Surface Finish |

Polished, Pickled, Annealed, or Custom |

|

Pressure Rating |

Up to 100 MPa (contingent on dimensions) |

Applications

- Chemical & Petrochemical: Heat exchangers, reactor tubes, and pipelines for aggressive media.

- Oil & Gas: Downhole tubing, subsea components, and sour gas handling.

- Aerospace: Combustion chambers, exhaust systems, and hydraulic lines.

- Nuclear & Power: Steam generator tubing and coolant systems.

Quality Assurance

- Certifications: Compliant with ASTM, NACE MR0175, and PED 2014/68/EU.

- Testing: 100% non-destructive testing (UT, RT), PMI verification, and intergranular corrosion testing.

LATEST RECOMMENDED

Related products

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074