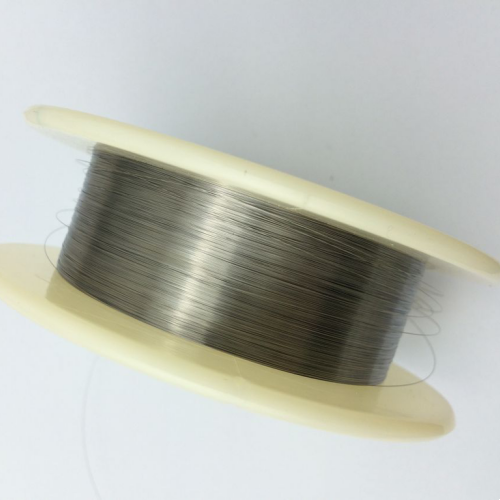

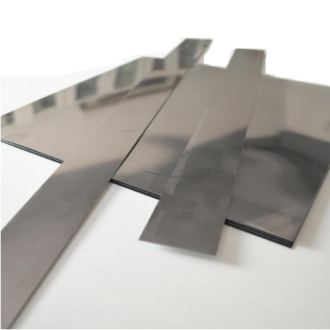

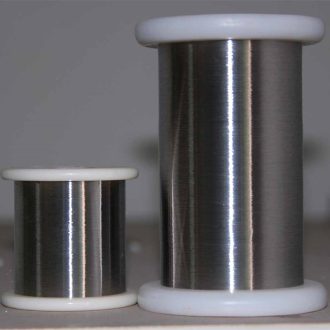

Molybdenum Wire

| Type | Kind | Molybdenum content (%) | Total amount of other elements (%) | Content of each element (%) | Content of elements appended (%) |

| MO1 | D | 99.93 | 0.07 | 0.01 | – |

| X | |||||

| MO2 | R | 99.90 | 0.10 | 0.01 | – |

| MO3 | G | 99.33 | 0.07 | 0.01 | 0.20~0.60 |

Molybdenum wire is wire material made of high quality molybdenum powder, refined by powder metallurgy, drawing and other processes. It has excellent physical and chemical properties and is widely used in high temperature, high pressure, corrosive and other special environments. With its excellent performance, molybdenum wire has become an indispensable key material in electronics, semiconductor, aerospace, medical and many other fields.

Features of Molybdenum Wire:

High melting point and high temperature resistance: Molybdenum has a melting point of up to 2623 ° C, which allows it to maintain good mechanical properties and chemical stability in high temperature environments, and is not easily deformed or melted.

High strength and hardness: Molybdenum wire has high tensile strength and hardness, and can withstand large loads and wear.

Good conductivity and thermal conductivity: Molybdenum is a material with excellent conductivity and thermal conductivity, suitable for making various electrical and thermal conductive components.

Low coefficient of thermal expansion: Molybdenum has a low coefficient of thermal expansion, good dimensional stability, and is not easily deformed under temperature changes.

Good corrosion resistance: Molybdenum has good corrosion resistance in many acidic and alkaline media, which can meet the requirements of harsh environments.

Machinability: Molybdenum wire has good plasticity and processability, making it easy for subsequent processing such as cutting, bending, welding, etc.

High purity: The molybdenum wire produced by our company uses high-purity raw materials with low impurity content and stable and reliable quality.

Main Uses of Molybdenum Wire:

Electronics industry:

Vacuum electronic tube/light bulb heating element: Utilizing its high melting point and high temperature strength, it is used as the cathode and heating wire for vacuum tubes, light bulbs and other devices.

Semiconductor devices: Used as lead material, back electrode, etc. in the semiconductor manufacturing process.

X-ray tubes: Used as target materials and cathodes for X-ray tubes.

High-temperature furnace:

High-temperature heating elements: used as heating wires and heat generators in high-temperature furnaces, suitable for vacuum furnaces, sintering furnaces, and heat treatment furnaces, etc.

Cutting Tools: Molybdenum Wire 0.18mm used for Wire Cutting Machines

Wire Cutting Machines: Utilizing the high strength and precision of molybdenum wires, precision cutting is carried out in mold processing and other fields.

Aerospace:

High-temperature structural parts: Used in the manufacture of high-temperature structural parts such as rocket engine nozzles and high-temperature bearings.

Medical field:

Medical Devices: Used in the manufacture of certain special medical device components.

Other fields:

Chemical industry: used to manufacture corrosion-resistant vessels.

Glass industry: used as electrode in glass melting furnace.

EDM: Used as electrode material for EDM by utilizing its excellent electrical conductivity.

Specifications Of Pure Molybdenum Wire:

Diameter: 0.018mm~3.0mm (can be customized according to customer needs)

Length: Customizable

Surface condition: Black/cleaned

Purity: above 99.95%

Why Choose FOTMA Molybdenum Wire?

Quality assurance: FOTMA has advanced production equipment and strict quality control system to ensure the high purity and performance stability of our products.

Experienced: We have extensive experience in the production and processing of molybdenum materials, and can provide customers with professional technical support and customized solutions.

Reasonable price: We are committed to providing customers with cost-effective products and services.

Quick response: We have an efficient sales team that can promptly respond to customer needs and provide fast delivery services.

CONTACT US NOW TO GET LATEST MOLYBDENUM WIRE PRICE!

LATEST RECOMMENDED

Related products

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074