Molybdenum Spray Wire

|

Grade |

Mo-1 | Grade |

Mo-1 |

||

|

The impurity content is not more than % |

Pb |

— | The impurity content is not more than % | Si |

0.003 |

|

Bi |

— | Ca |

0.002 |

||

|

Sn |

— | Mg |

0.002 |

||

|

Sb |

— | P |

0.001 |

||

|

Cd |

— | C |

0.020 |

||

|

Fe |

0.006 | O |

0.003 |

||

|

Ni |

0.003 | N |

0.003 |

||

|

Al |

0.002 | — |

— |

||

FOTMA High-Purity Molybdenum Spray Wire: Superior Performance, Breakthrough in Single Weight, Boosting Efficient Surface Engineering

We’re proud to introduce our next-generation high-purity molybdenum spraying wire, designed to meet the rigorous demands of surface engineering applications. As a leading materials provider, we are committed to delivering the highest quality products to help you achieve exceptional coating performance.

Exceptional Purity, Achieving Superior Performance:

Our molybdenum spraying wire is manufactured using advanced production techniques, ensuring exceptional purity. High-purity molybdenum wire offers the following significant advantages:

- Excellent Spraying Performance: The higher purity of the molybdenum wire allows for more uniform melting and better atomization during spraying, resulting in dense, even coatings, which improves spraying efficiency and coating quality.

- Superior Coating Adhesion: Coatings formed with high-purity molybdenum wire exhibit stronger adhesion to the substrate, ensuring the durability and longevity of the coating.

- Stable Chemical Properties: High-purity molybdenum demonstrates excellent resistance to corrosion, high temperature, and wear, ensuring the coating remains stable and reliable even in extreme environments.

- Low Impurity Pollution: High-purity molybdenum wire minimizes the introduction of impurities, reducing pollution to spraying equipment and the environment.

Breakthrough in Single Weight, Meeting Large-Scale Application Needs:

FOTMA’s molybdenum thermal spraying wire has achieved a significant breakthrough in single weight, going up to 25kg. This significant increase in single weight provides a more convenient solution for large-scale component surface spraying:

- Reduced Wire Change Frequency: The increased single weight reduces the frequency of changing the molybdenum wire during spraying, significantly improving production efficiency and reducing production costs.

- Meeting Large Component Requirements: The extra-large single weight of the wire meets the demand for continuous spraying on large components, ensuring consistency and uniformity of coating thickness.

- More Economical Choice: Fewer wire changes mean reduced downtime and material waste, providing a more economical solution for customers.

Wide Range of Applications:

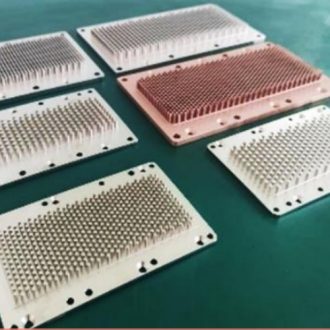

FOTMA’s high-purity molybdenum spraying wire is suitable for various spraying processes, such as flame spraying, plasma spraying, and arc spraying, and is widely used in the following fields:

- Mechanical Manufacturing: Repairing worn parts, improving the hardness and wear resistance of components.

- Aerospace: Manufacturing high-temperature, wear-resistant components, improving the reliability of aircraft.

- Energy Industry: Spraying components used in high-temperature and high-pressure environments, improving equipment operating efficiency.

- Automotive Industry: Used for surface strengthening of components like piston rings and synchronizers.

- Medical Equipment: Used in the preparation of biocompatible coatings.

Molybdenum spraying wire Properties:

- The weight of single wire is up to 20-25kg without any welded joint, which results in enhancing the efficiency and decreasing the operating costs.

- Diameter: 3.175mm, 2.3mm-1.41mm

- Tolerance: 3. 175mm + / -0. 025mm or + 0 / -0. 05mm

- 3mm-1. 45mm + / -0. 02mm + 0 / -0. 05mm

- Tensile strength: >700-900N / mm2

- Elongation: >20-5%

FOTMA: Your Trusted Partner

By choosing FOTMA, you will receive:

- High-Quality Products: We strictly control the production process to ensure that every batch of molybdenum wire meets the highest industry standards.

- Professional Technical Support: We have an experienced technical team to provide you with comprehensive technical advice and solutions.

- Customized Services: We can provide customized molybdenum wire products and packaging solutions to meet your specific needs.

- Reliable Supply Capability: We have an efficient production and logistics system to ensure timely and stable delivery.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074