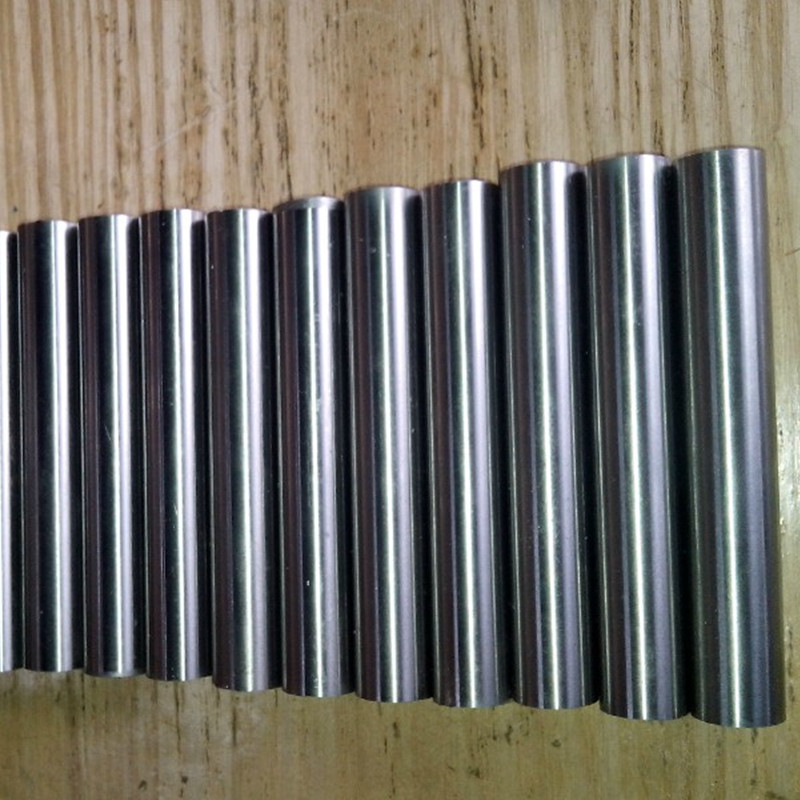

Molybdenum Rod

|

Grade |

The impurity content is not more than % |

|||||||

|

Fe |

Ni | Al | Si | Mg | C | N |

O |

|

|

Mo-1 |

0.01 | 0.005 | 0.002 | 0.01 | 0.005 | 0.01 | 0.003 |

0.008 |

|

Mo-2 |

0.01 | 0.005 | 0.005 | 0.01 | 0.005 | 0.01 | 0.003 |

0.02 |

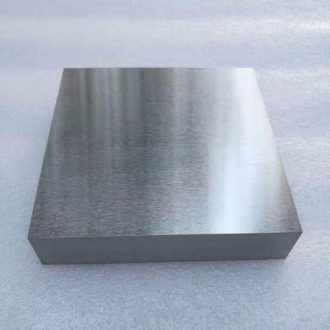

Pure molybdenum rods are made from high purity molybdenum metal through a precision machining process. Molybdenum is a rare metal with a high melting point, high strength, high hardness, good electrical conductivity and corrosion resistance, making it widely used in high temperature, high pressure and corrosive environments. China molybdenum rod gives full play to these excellent properties of molybdenum and have become an indispensable and important material in many industrial fields.

Pure molybdenum rods Properties:

Ultra-high melting point: The melting point of molybdenum is as high as 2623 ℃, which enables it to maintain good mechanical strength and stability in high temperature environments, and is not easily deformed.

High strength: Pure molybdenum rods have high strength and hardness, which can resist stress at high temperatures and ensure their stable operation in high-temperature environments.

Good conductivity: Molybdenum has good conductivity, which enables it to effectively conduct current and reduce resistance losses.

Good thermal conductivity: Molybdenum conducts heat efficiently, contributing to heat dissipation and temperature control.

Low coefficient of thermal expansion: Molybdenum has a low coefficient of thermal expansion, which makes it less susceptible to dimensional deformation during temperature changes and ensures its stability in high-temperature environments.

Excellent corrosion resistance: Molybdenum has good corrosion resistance in acids, alkalis and other corrosive media, enabling it to work stably for a long time in harsh environments.

Good processability: pure molybdenum rods can be processed through a variety of machining methods, made of different specifications and sizes of products to meet the needs of various applications.

High temperature creep resistance: Under long-term high-temperature loads, pure molybdenum rods have excellent creep resistance and are not easily deformed, which makes them significantly advantageous in applications such as high-temperature furnaces.

Low vapor pressure: At high temperatures, molybdenum has a lower vapor pressure and does not undergo excessive volatilization or loss, ensuring its application performance in a vacuum environment.

Molybdenum rod Surface Finish

Black – Surface is “as swaged” or “as drawn”; retaining a coating of processing lubricants and oxides.

Cleaned – Surface is chemically cleaned to remove all lubricants and oxides.

Ground – Surface is centerless ground to remove all coating and to achieve precise diameter control.

CONTACT US NOW TO GET LATEST MOLYBDENUM ROD PRICE!

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074