Molybdenum Plate Moly Sheet

Molybdenum Sheet Specifications:

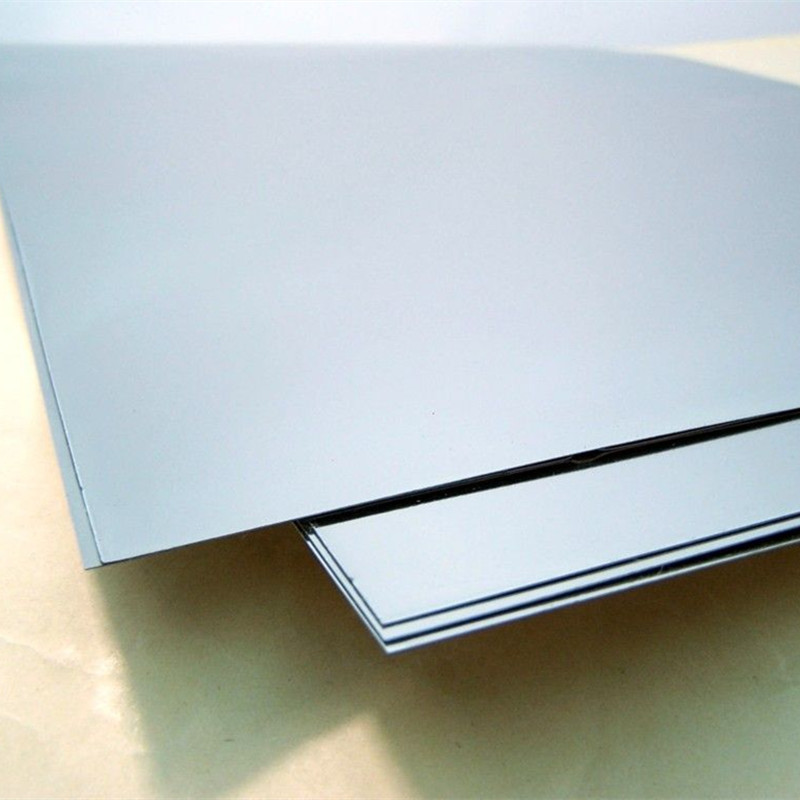

Thickness: < 0.15 mm Max size: 150 x 1000 mm

Thickness: 0.20 mm Max size: 500 x 1500 mm

Thickness: 0.25 – 0.4 mm Max size: 610 x 3000 mm

Thickness: 0.5 – 2.0 mm Max size: 610 x 1500 mm

Thickness: 2.5 – 3.5 mm Max size: 500 x 1000 mm

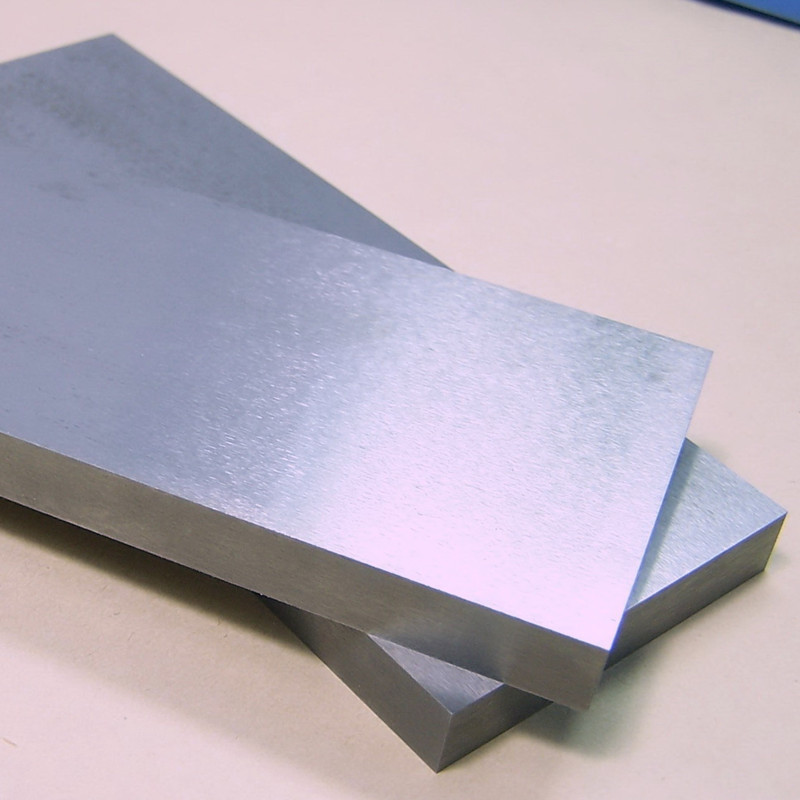

Molybdenum plate is a high-performance sheet made of high-purity metal molybdenum (Mo) through powder metallurgy, hot rolling, cold rolling and precision machining processes. As a representative of refractory metals, molybdenum has an extremely high melting point (2620°C), excellent high-temperature strength, outstanding corrosion resistance, and good thermal and electrical conductivity, which makes molybdenum sheet an ideal choice for material applications in extreme environments. It is widely used in semiconductor manufacturing, high-temperature industry, aerospace, nuclear energy and medical equipment, and is one of the core materials supporting modern technology and high-end manufacturing.

Characteristics and Advantages of Molybdenum Sheet

- Extreme High Temperature Stability

-Ultra-high melting point: moly sheet can work stably for a long time in a high temperature environment above 1600°C. It has excellent thermal shock resistance and is suitable for high temperature furnace lining, heat insulation screen and other scenarios.

– Low Coefficient of Thermal Expansion: small dimensional changes at high temperatures, safeguarding the structural stability of precision equipment.

- Excellent Mechanical Properties

– High strength and hardness: tensile strength up to 500~800 MPa, still maintains excellent creep resistance and deformation resistance at high temperature.

– Wear and corrosion resistance: good resistance to molten metals, acidic gases and some chemical media, long service life.

- High Purity & Functionality: Ultra High Purity.

– Ultra-high purity: purity ≥99.95%, very low impurity content, to meet the semiconductor sputtering targets, single crystal growth furnace hot field components and other stringent requirements.

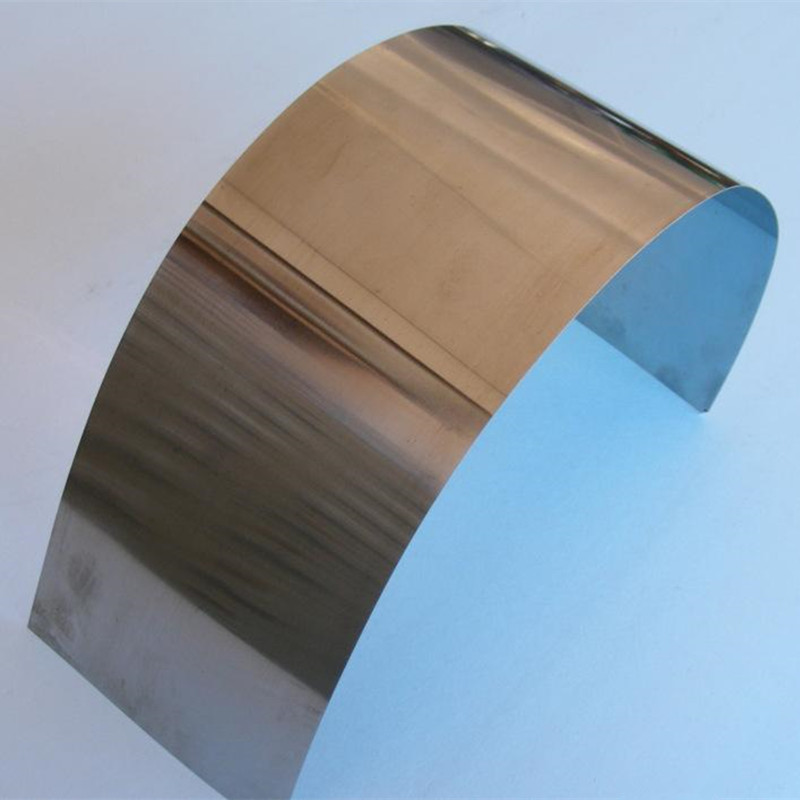

– Excellent process ability: supports secondary processing such as cutting, stamping, welding, polishing, etc., and can be customized with complex shapes and surface treatments.

- Multi-functional Application Adaptation: Multi-functional Application Adaptation

– Diversified specifications: Thickness range from 0.1mm to 50mm, width up to 600mm, supporting the supply of a full range of ultra-thin foils to thick plates.

– Surface treatment optimization: Polishing (mirror/matte), plating (nickel, titanium), oxidation treatment, etc. are available to enhance oxidation resistance or interfacial bonding.

China Molybdenum Plate Application:

- Semiconductor and electronics industry

– Sputtering targets: used in the thin film deposition process of integrated circuits and display panels to guarantee the uniformity of high-purity films.

– Electronic packaging substrate: as a high thermal conductivity substrate, used for power devices, LED chip heat dissipation.

- High-temperature industrial equipment

– High-temperature furnace core components: heat-insulating screens, heating element supports, sapphire crystal growth furnace crucibles, resistant to long-term extreme heat environment.

– Glass & Metallurgy Industry: glass furnace electrodes, metal melting vessel linings, resistance to molten material erosion.

- Aerospace and nuclear energy: lining of rocket engine nozzles, resisting the erosion of molten substances.

-Rocket motor nozzle lining: Resistant to high temperature gas washout, safeguarding structural integrity.

– Nuclear reactor components: neutron absorbing plates, radiation shielding materials to ensure safety and stability.

- Medical and Scientific Research Equipment: X-ray and CT equipment.

– X-ray and CT equipment target materials: high-energy ray window materials, both high density and low attenuation characteristics.

– Vacuum equipment cavities: used in particle gas pedals, vacuum coating machines, to maintain ultra-high vacuum environment.

- New energy field: Photovoltaic and lithium battery manufacturing

– Photovoltaic and lithium battery manufacturing: thin film solar cell back sheets, lithium battery sintered carrier plates, to improve production efficiency and product consistency.

FOTMA Molybdenum Sheet Metal Quality Control and Certification

– Stringent production standards: Follow international standards such as ASTM B386 and GB/T 3876 to ensure that chemical composition, grain size and mechanical properties are up to standard.

– Full Process Inspection: Adopting advanced technologies such as ultrasonic flaw detection (internal defect detection), laser thickness gauge (thickness tolerance ±0.01mm), and electron microscope (surface analysis) to guarantee product uniformity and reliability.

Services and support

Flexible customization: non-standard sizes, shaped cuts, pre-coated or composite-layered molybdenum sheets (e.g., molybdenum-copper composite sheets) are available upon request.

– Rapid Response: Molybdenum sheets of conventional specifications are available in stock, urgent orders are shipped within 72 hours, and global logistics and distribution are supported.

– Technical Collaboration: We provide full technical support for material selection, processing process optimization and failure analysis to help customers reduce costs and increase efficiency.

CONTACT US NOW TO GET LATEST MOLYBDENUM PLATE PRICE & MOLYBDENUM SHEET PRICE!

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074