Molybdenum Electrodes for Glass Melting

|

Parameter |

Molybdenum Electrode | Graphite Electrode | Platinum Electrode |

| Max Operating Temperature | 1700°C (coated) | 800°C |

1600°C |

|

Electrical Resistivity |

5.7×10⁻⁸ Ω·m | 8.0×10⁻⁶ Ω·m | 1.06×10⁻⁷ Ω·m |

| Thermal Conductivity | 138 W/m·K | 120 W/m·K |

71 W/m·K |

|

Typical Diameter |

25–150 mm | 50–300 mm |

10–50 mm |

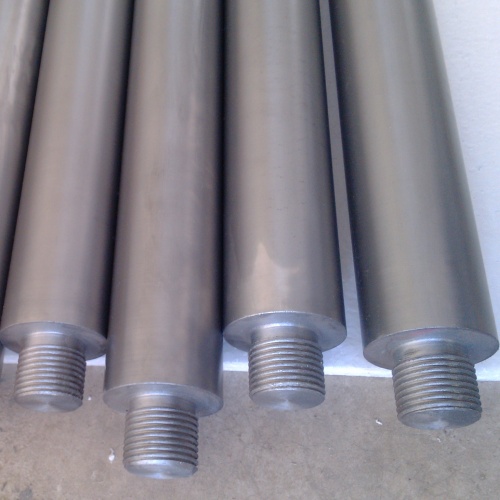

Molybdenum Electrodes for Glass Melting Furnaces: High-Performance Solutions for Precision Glass Production

Molybdenum electrodes are critical components in modern glass melting furnaces, enabling efficient and stable high-temperature processing of glass melts. Designed for environments exceeding 1500°C, these electrodes combine superior electrical conductivity, oxidation resistance, and thermal stability, making them indispensable for producing high-quality optical glass, borosilicate glass, and specialty glass products.

Key Advantages of Moly Electrode

- Extreme Temperature Resistance

- Operating Range: Up to 1700°C in oxidizing atmospheres (with protective coatings) and 2200°C in inert/vacuum environments.

- Maintain structural integrity and conductivity even under prolonged exposure to molten glass.

- Superior Oxidation Resistance

- MoSi₂ or Al₂O₃ Coatings: Protect electrodes from oxidation in oxygen-rich glass melts, extending lifespan by 3–4x compared to uncoated molybdenum.

- High Electrical Efficiency

- Low resistivity (5.7×10⁻⁸ Ω·m) ensures uniform current distribution, reducing energy consumption by 15–20% vs. graphite electrodes.

- Corrosion Resistance

- Resistant to aggressive glass components (e.g., sulfates, chlorides), minimizing erosion and contamination risks.

- Long Service Life

- Average lifespan of 12–18 months in continuous operation, outperforming graphite (6–8 months) and platinum-coated electrodes.

Why Choose Molybdenum Electrode

| Parameter | Molybdenum Electrode | Graphite Electrode | Platinum Electrode |

| Max Operating Temperature | 1700°C (coated) | 800°C | 1600°C |

| Electrical Resistivity | 5.7×10⁻⁸ Ω·m | 8.0×10⁻⁶ Ω·m | 1.06×10⁻⁷ Ω·m |

| Thermal Conductivity | 138 W/m·K | 120 W/m·K | 71 W/m·K |

| Typical Diameter | 25–150 mm | 50–300 mm | 10–50 mm |

| Coating Options | MoSi₂, Al₂O₃, Y₂O₃ | None | Platinum/Zirconia Composite |

| Lifespan (Continuous Use) | 12–18 months | 6–8 months | 24–36 months* |

| Cost Efficiency | High | Low | Very High |

*Platinum electrodes are cost-prohibitive for large-scale applications.

Applications in Glass Melting

- Optical Glass Production: Ensures bubble-free melting and homogeneity for lenses, fiber optics, and laser components.

- Borosilicate Glass: High thermal shock resistance aligns with the demands of laboratory glassware and cookware.

- LCD/OLED Glass Substrates: Precise temperature control prevents defects in ultra-thin display glass.

- Specialty Glass: Suitable for lead-crystal, uranium glass, and radiation-shielding glass melts.

Design & Customization

- Dimensions: Custom diameters (15–200 mm), lengths (500–3000 mm), and threaded/smooth ends.

- Coatings:

- MoSi₂: Optimal for temperatures up to 1700°C in oxidizing conditions.

- Al₂O₃: Enhanced corrosion resistance in sulfate-rich melts.

- Cooling Systems: Integrated water-cooled holders to manage peripheral heat.

- Certifications: Compliant with ASTM F2896, RoHS, and ISO 18544 standards.

Why Choose FOTMA Molybdenum Electrodes?

- Extended Lifespan: Advanced coating technologies reduce replacement downtime.

- Energy Savings: High conductivity lowers power consumption per ton of molten glass.

- Technical Support: On-site installation guidance and real-time thermal performance monitoring.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074