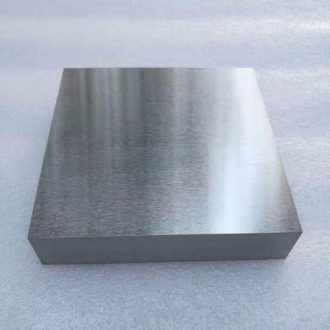

Molybdenum Crucible

Molybdenum Crucibles Specifications:

Material Purity: 99.95% (3N5) or 99.97% (3N7) or higher, customized to order

Shape:

Cylindrical: Regular round shape, customized with different inner diameters, heights and wall thicknesses.

Conical: For certain melting requirements, to minimize the residue of molten material

Square/Rectangular: for specific heating or melting processes

Lidded: Available in lidded or unlidded design to optimize the melting process

Special customization: customized according to customer drawings or samples

Molybdenum Crucible: High Temperature Resistant, Corrosion Resistant, Helps High Temperature Smelting and Experimentation

FOTMA high-purity molybdenum crucibles designed to meet the demands of high-temperature, high-vacuum or corrosive environments. Our superior materials science and manufacturing processes provide you with high performance, reliable and durable molybdenum crucibles for success in critical applications such as pyro metallurgy, vacuum vapor deposition, crystal growth and more.

Advantages of Molybdenum Crucibles

Superior High Temperature Resistance: Molybdenum has an extremely high melting point (2623°C), molybdenum crucibles can be used in a wide range of high temperature applications with long term stability at temperatures as high as 2000°C.

Excellent Corrosion Resistance: Pure molybdenum has excellent corrosion resistance and is resistant to a wide range of molten metals, glass, oxides, and other substances, extending the life of the crucible.

Extremely high purity: High purity molybdenum powder is selected, and advanced sintering and processing technology is adopted to ensure that the crucible has extremely low impurity content, which reduces the contamination of melting materials and ensures the purity of experimental or production results.

Good thermal stability: Molybdenum crucible has excellent thermal shock performance, can maintain structural stability during rapid temperature rise and fall, not easy to crack or deformation.

Accurate Dimensional Control: FOTMA utilizes precision machining techniques to ensure that each crucible has accurate dimensions and uniform wall thickness to meet the dimensional accuracy requirements of a wide variety of applications.

Applications of Molybdenum Crucible

Rare Earth Smelting: For melting rare earth metals, alloys or compounds.

Vacuum Melting: Melting of high purity metals and alloys under vacuum or inert atmosphere.

Vacuum Evaporation: Used as an evaporation source for thin film deposition.

Crystal growth: for sapphire, monocrystalline silicon and other crystal growth.

High-temperature experiments: for scientific research under various high-temperature conditions.

Glass melting: for melting special glass.

Ceramic sintering: for high-temperature sintering of ceramic materials.

Chemical analysis: for the melting and analysis of corrosive substances.

Other high temperature or corrosive applications

Specifications:

Material Purity: 99.95% (3N5) or 99.97% (3N7) or higher, customized to order

Shape:

Cylindrical: Regular round shape, customized with different inner diameters, heights and wall thicknesses.

Conical: For certain melting requirements, to minimize the residue of molten material

Square/Rectangular: for specific heating or melting processes

Lidded: Available in lidded or unlidded design to optimize the melting process

Special customization: customized according to customer drawings or samples

Sizes:

Inside diameter: 10mm to 500mm or larger, customized to customer requirements

Height: 10mm to 500mm or greater, customized to customer requirements

Wall thickness: 1mm to 20mm or other customized thicknesses

Volume: from a few milliliters to tens of liters, customized on request

Surface Finish: Mechanical polishing, electrolytic polishing or alkaline cleaning are available.

Other features: Trunnions, flanges, etc. can be customized.

Why Choose Us:

High quality assurance: Using high quality molybdenum raw materials, through strict quality control to ensure excellent performance and stable quality.

Professional Technical Support: Experienced engineers provide you with comprehensive technical advice and support to help you choose the most suitable solution.

Customized service: We can provide customized molybdenum crucible design, production and surface treatment service according to your specific needs.

Quick response: we have efficient production and logistics team to ensure timely delivery and meet your project requirements.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074