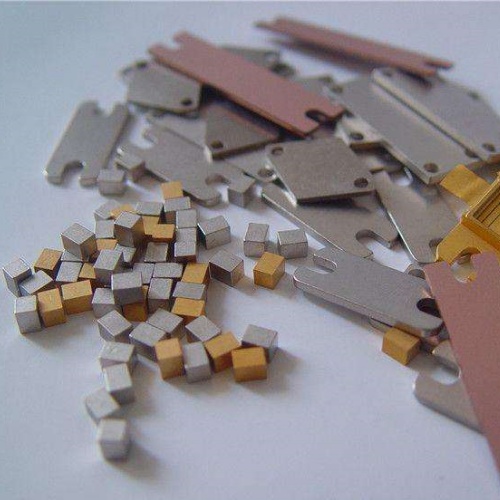

Molybdenum Copper Alloy (MoCu) Heat Sink

Why Choose FOTMA MoCu?

✅ Global Alternative: Performance rivals Plansee and H.C. Starck at 60–70% of imported brands’ cost.

✅ Full Customization: Adjust Mo/Cu ratios (50/50 to 85/15), precision etching, microchannel machining, and more.

✅ Military-Grade Quality: 100% X-ray inspection + helium leak testing, compliant with GJB548B and MIL-STD-883 standards.

FOTMA Molybdenum Copper Alloy (MoCu) Heat Sink Alloy: Lightweight, Ultra-Dense, and Precision-Cooling for Electronics & Defense

Lightweight Yet Ultra-Dense, Engineered for Efficient Thermal Dissipation FOTMA molybdenum copper (MoCu) alloy achieves near-100% density, nanocrystal line structure (grain size ≤5μm) , and exceptional leak-tightness (helium leak rate <5×10⁻⁹ Pa·m³/s), surpassing traditional thermal management materials. Compared to tungsten-copper (WCu), MoCu boasts 30% lower density, superior rollability, and stamping compatibility, making it ideal for mass production of ultra-thin heat sinks.

Breakthrough Advantages of Molybdenum Copper

- Ultra-Dense Structure & Hermetic Reliability

- Vacuum Hot Pressing + HIP Sintering: Density ≥99.8%, near-zero porosity, and thermal conductivity up to 190–240 W/(m·K) , matching leading global competitors.

- Atomic-Level Sealing: Helium leak rate <5×10⁻⁹ Pa·m³/s, meeting aerospace-grade hermeticity standards to prevent oxidation failure in microelectronics.

- Lightweight & Cost-Effective Manufacturing

- Density: 9.5–10.5 g/cm³ (vs. WCu ≥14 g/cm³): Reduces component weight for 5G mobile devices, drones, and other weight-sensitive applications.

- Exceptional Rollability: Rolled into ultra-thin foils down to 0.05mm (30% thinner than WCu), ideal for chip-scale vapor chambers.

- High-Precision Stamping: Enables complex-shaped heat sink parts at 40% lower mass-production costs and 50% faster lead times.

- High-Temperature Stability & Extended Lifespan

- Creep Resistance at 800°C: Maintains >85% strength retention for high-power laser mounts and military radar T/R module cooling.

- Low CTE (6.0–8.5×10⁻⁶/°C): Matches GaN/SiC chips, reducing thermal stress by 70% in power electronics.

Key Applications of Our Copper Moly Material

| Industry | Challenges | FOTMA MoCu Solutions |

| Microelectronics | 5G RF module overheating, sealing failures | 0.1mm ultra-thin MoCu vapor chambers (240 W/m·K thermal conductivity) with 100% helium leak compliance. |

| Defense Cooling | Hypersonic vehicle transpiration cooling under thermal shock | Custom gradient-porous MoCu structures withstand 2000°C transient heat, tripling cooling efficiency. |

| Electrode Manufacturing | Short electrode lifespan in resistance welding | Mo70Cu30 electrodes last 5x longer than pure copper, maintaining 85% IACS conductivity. |

| Consumer Electronics | Lightweight cooling for smartphones/AR devices | Stamped heat spreaders: 40% lighter, 0.3mm thickness, enabling slim designs. |

Why Choose FOTMA MoCu Moly Copper?

✅ Global Alternative: Performance rivals Plansee and H.C. Starck at 60–70% of imported brands’ cost.

✅ Full Customization: Adjust Mo/Cu ratios (50/50 to 85/15), precision etching, microchannel machining, and more.

✅ Military-Grade Quality: 100% X-ray inspection + helium leak testing, compliant with GJB548B and MIL-STD-883 standards.

Rapid Production & Delivery

- 3-day sampling for standard grades, free samples available.

- Rolled foil width ≤600mm, thickness tolerance ±0.002mm.

- Monthly capacity: 20 tons, with 72-hour expedited orders.

FOTMA Moly Copper Alloy – Where Lightweight Meets Uncompromised Thermal Mastery.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074