IGBT Heat Sink Substrates

|

Property |

Diamond-Copper Substrate |

High-Silicon Aluminum Substrate |

| Thermal Conductivity | 500–800 W/m·K |

150–200 W/m·K |

|

CTE |

4–8 ppm/°C (matches Si/SiC chips) | 7–12 ppm/°C (matches DBC substrates) |

| Density | 5.2–6.0 g/cm³ |

2.4–2.7 g/cm³ (ultra-lightweight) |

|

Applications |

Ultra-high-power motor controllers | Mid-to-high power with weight sensitivity |

IGBT Heat Sink Substrates: High-Efficiency Thermal Management Solution for New Energy Vehicle Power Modules

Critical Challenges: IGBT Thermal Failure and Reliability Issues

IGBT power modules in new energy vehicle motor controllers generate significant heat during high-frequency switching and continuous operation. For every 10°C rise in temperature, the risk of module failure doubles, directly impacting motor efficiency and vehicle reliability. As the core heat dissipation component, the heat sink substrate must deliver:

- High Thermal Conductivity: Rapid heat transfer from power chips;

- Low Thermal Expansion Coefficient (CTE) : Precise CTE matching (4–8 ppm/°C) with chips, Direct Bonded Copper (DBC) substrates, and other components to prevent thermal stress;

- Compact and Lightweight Design: Aligns with motor controller miniaturization trends;

- Structural Durability: Resists vibration, mechanical shock, and long-term thermal cycling.

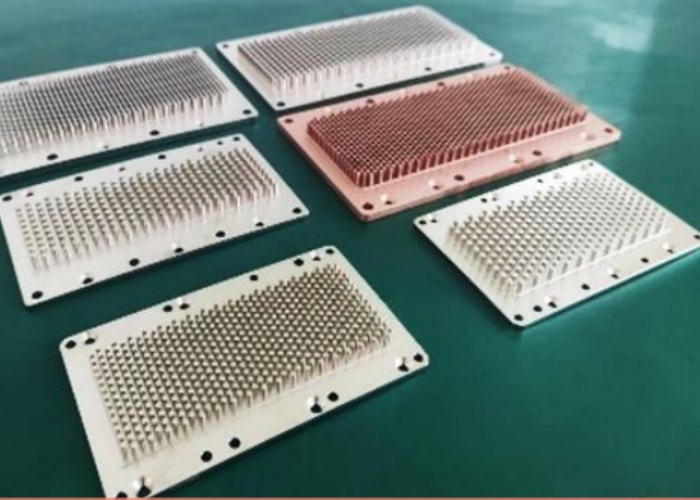

Pin-Fin Heat Sink Substrates: Breakthrough Design and Advanced Material Technology

Core Innovation: Pin-Fin Structure

- 3D Pin-Fin Array: Additive manufacturing or precision stamping creates high-density micro pin-fins on the substrate surface, increasing heat dissipation area by 50%–300% compared to flat substrates, dramatically improving convective heat transfer.

- Turbulence-Optimized Design: Pin-fin geometry and layout are engineered via fluid dynamics simulations to accelerate airflow and reduce thermal resistance.

- Lightweight and Compact: Maintains localized cooling efficiency while reducing overall volume by 30% , meeting high power density requirements for new energy vehicles.

Material Advancements: High-Performance Composites

Using diamond-copper (Dia/Cu) or high-silicon aluminum alloy as core materials achieves unprecedented performance:

| Property | Diamond-Copper Substrate | High-Silicon Aluminum Substrate |

| Thermal Conductivity | 500–800 W/m·K | 150–200 W/m·K |

| CTE | 4–8 ppm/°C (matches Si/SiC chips) | 7–12 ppm/°C (matches DBC substrates) |

| Density | 5.2–6.0 g/cm³ | 2.4–2.7 g/cm³ (ultra-lightweight) |

| Applications | Ultra-high-power motor controllers | Mid-to-high power with weight sensitivity |

Material Advantages:

- Diamond-Copper (Dia/Cu) : Thermal conductivity nearly 2x higher than pure copper and CTE closely matched to chips, eliminating thermal mismatch risks.

- High-Silicon Aluminum Alloy: Density 1/3 of copper, ideal for weight-sensitive applications; nickel/gold plating enhances corrosion resistance and sealing.

Four Core Advantages for Automotive-Grade Thermal Excellence

- Ultra-Fast Heat Dissipation, Precision Temperature Control

Substrate thermal conductivity ≥500 W/m·K with pin-fin structures reduces IGBT junction temperature by 15–25°C, extending module lifespan by 30%+ . - Zero Thermal Stress Design

CTE-matched materials ensure >100,000 cycles (-40°C to 150°C), far exceeding industry benchmarks. - Lightweight Integration

40%–60% lighter than traditional copper substrates while maintaining equivalent performance, boosting vehicle efficiency and range. - Extreme Environment Durability

Compliant with AEC-Q101 automotive standards, resisting vibration (20G), humidity (85°C/85% RH), and salt spray (1,000 hours) for global deployment.

Applications: Empowering New Energy Vehicle Powertrains

- Motor Controllers: Thermal management for 400V/800V high-voltage IGBT modules;

- On-Board Chargers (OBC) : High-power SiC module cooling;

- Battery Management Systems (BMS) : Efficient heat dissipation for master control chips;

- E-Drive Systems: Key component of integrated cooling solutions.

Custom Solutions and Full-Cycle Assurance

- Tailored Designs: Customize pin-fin height (1–5mm), density, and material ratios to fit module dimensions and thermal demands;

- Advanced Manufacturing: Vacuum brazing/diffusion bonding ensures robust pin-fin bonding (shear strength >50 MPa);

- Full Lifecycle Testing: Thermal simulations, FMEA, bench tests, and real-world validation guarantee compliance.

Choose our IGBT Pin-Fin Heat Sink Substrates—where material innovation and structural excellence redefine reliability and efficiency for new energy vehicles!

Request free samples and thermal simulation reports today!

Thermal Management, Simplified. Drive the Future with Confidence!

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074