Hot Zone Thermal Shields

|

Parameter |

Tungsten (W) | Molybdenum (Mo) | Composite (W-Mo) |

| Max Operating Temperature | 2200°C | 1800°C |

2000°C |

|

Density |

19.3 g/cm³ | 10.2 g/cm³ | 14.8 g/cm³ |

| Thermal Conductivity | 173 W/m·K | 138 W/m·K |

155 W/m·K |

|

Thickness Options |

0.5–3.0 mm | 0.5–3.0 mm | 0.5–3.0 mm |

| Surface Finish | Polished/Coated | Polished/Coated |

Polished/Coated |

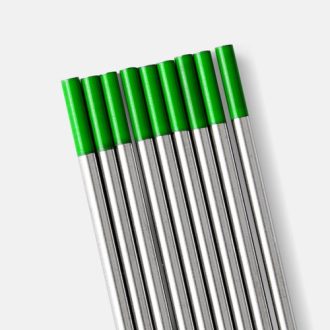

Tungsten-Molybdenum (W-Mo) Thermal Shields for High Temperature Furance:

Tungsten-molybdenum hot zone shielding are high-performance components designed for extreme-temperature industrial applications, such as vacuum furnaces, sintering systems, and aerospace thermal processing equipment. Combining the exceptional properties of tungsten and molybdenum, these screens deliver unparalleled thermal management, durability, and efficiency in high-heat environments.

Key Advantages of W-Mo Hot Zone Shielding

- Ultra-High Temperature Resistance

- Withstand continuous operation up to 2200°C (tungsten) and 1800°C (molybdenum), ideal for processes like ceramic sintering, nuclear material annealing, and advanced alloy treatment.

- Superior Thermal Insulation

- Multi-layer reflective design minimizes radiant heat loss, improving furnace energy efficiency by 30–40% compared to traditional graphite screens.

- Low Thermal Expansion

- Coefficient of thermal expansion (CTE): 4.5×10⁻⁶/°C (W) and 5.3×10⁻⁶/°C (Mo) , reducing structural stress and deformation during rapid temperature cycling.

- High Purity & Vacuum Compatibility

- Ultra-low outgassing rate (<1×10⁻⁶ Pa·m³/s) ensures stable vacuum environments (up to 10⁻⁵ Pa), critical for semiconductor and aerospace applications.

- Long Service Life

- Resistant to oxidation, creep, and thermal fatigue, offering 2–3x longer lifespan than conventional nickel-based alloys.

Technical Parameters

| Parameter | Tungsten (W) | Molybdenum (Mo) | Composite (W-Mo) |

| Max Operating Temperature | 2200°C | 1800°C | 2000°C |

| Density | 19.3 g/cm³ | 10.2 g/cm³ | 14.8 g/cm³ |

| Thermal Conductivity | 173 W/m·K | 138 W/m·K | 155 W/m·K |

| Thickness Options | 0.5–3.0 mm | 0.5–3.0 mm | 0.5–3.0 mm |

| Surface Finish | Polished/Coated | Polished/Coated | Polished/Coated |

| Vacuum Performance | ≤1×10⁻⁶ Pa·m³/s | ≤1×10⁻⁶ Pa·m³/s | ≤1×10⁻⁶ Pa·m³/s |

| Typical Applications | Single-crystal growth,<br>High-purity metal sintering | Brazing furnaces,<br>Heat treatment | Aerospace component processing,<br>Ultra-high-temperature R&D |

Thermal Shields Applications

- Vacuum Furnaces: Optimize thermal uniformity and reduce energy consumption.

- Semiconductor Manufacturing: Ensure contamination-free annealing of silicon wafers.

- Aerospace: Critical for turbine blade coating and composite curing.

- Advanced Material R&D: Enable stable environments for high-entropy alloy synthesis.

Customization & Support

- Tailored Designs: Adjustable layer counts, shapes (cylindrical, flat, modular), and mounting configurations.

- Coating Options: Alumina or yttria coatings for enhanced oxidation resistance.

- Technical Services: Free thermal simulation, installation guidance, and 24/7 after-sales support.

Contact Us

Elevate your thermal processing efficiency with our tungsten-molybdenum insulation solutions. Request a quote or consult our engineers for application-specific optimization!

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074