Diamond Composite Materials

|

Property |

Diamond-Copper (Dia/Cu) | Diamond-Aluminum (Dia/Al) |

| Thermal Conductivity | 500–800 W/m·K |

400–600 W/m·K |

|

CTE |

4–8 ppm/°C | 6–10 ppm/°C |

| Density | 5.2–6.0 g/cm³ |

3.0–3.5 g/cm³ (lightweight champion) |

|

Ideal Use Cases |

High-power lasers, EV power modules |

UAVs, satellites, 5G RF devices |

Diamond Composite Materials: The Ultimate Solution for High-Performance Thermal Management

Revolutionizing Heat Dissipation with Diamond-Metal Composites

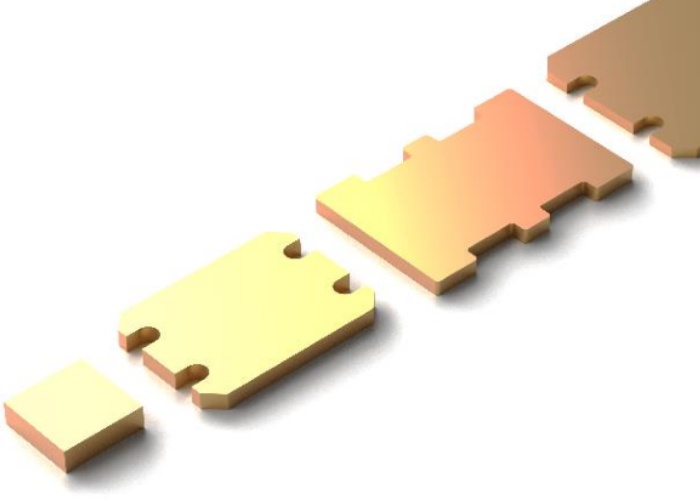

By integrating synthetic diamond particles into high-thermal-conductivity metal matrices (Ag, Cu, Al) through advanced composite manufacturing, diamond/metal composites achieve an unprecedented combination of ultra-high thermal conductivity and low thermal expansion, making them the next-generation material for high-power electronic packaging and thermal management.

Diamond-Copper (D/Cu) Composite: The Thermal Performance Benchmark

Material Structure

D/Cu is a matrix composite of synthetic diamond powder and copper alloy. Utilizing premium lab-grown diamonds with intrinsic thermal conductivity of 1,000 W/m·K and near-zero thermal expansion, this material achieves perfect interfacial metallurgical bonding under optimized processing, delivering exceptional thermal and mechanical properties.

Key Advantages

- Unmatched Thermal Performance:

- Thermal Conductivity: 500–800 W/m·K (adjustable based on diamond-to-copper ratio);

- Low CTE: 4–8 ppm/°C, precisely matching semiconductor materials (e.g., Si, GaN, SiC) to minimize thermal stress.

- Design Flexibility:

- Adjust diamond content (40%–70%) to balance thermal conductivity and CTE for specific applications.

- Surface Engineering:

- Compatible with Ni/Au plating for hermetic sealing, oxidation resistance, and solder ability.

- Weight Reduction:

- Density 5.2–6.0 g/cm³, 30% lighter than traditional tungsten-copper (W/Cu) heat sinks.

Diamond-Aluminum (D/Al) Composite: Lightweight Alternative

Material Profile

Similar to D/Cu but with aluminum as the matrix, D/Al offers even greater weight savings while maintaining competitive thermal performance:

- Thermal Conductivity: 400–600 W/m·K;

- CTE: 6–10 ppm/°C;

- Density: 3.0–3.5 g/cm³, 40% lighter than D/Cu, ideal for aerospace and portable electronics.

Why Choose D/Al?

- Optimized for applications where lightweight design is critical without compromising thermal management efficiency.

Dia/Cu vs. Dia/Al: Tailoring Solutions to Your Needs

| Property | Diamond-Copper (D/Cu) | Diamond-Aluminum (D/Al) |

| Thermal Conductivity | 500–800 W/m·K | 400–600 W/m·K |

| CTE | 4–8 ppm/°C | 6–10 ppm/°C |

| Density | 5.2–6.0 g/cm³ | 3.0–3.5 g/cm³ (lightweight champion) |

| Ideal Use Cases | High-power lasers, EV power modules | UAVs, satellites, 5G RF devices |

Applications: Where Diamond Composites Excel

- Power Electronics: IGBT modules, motor controllers, and SiC/GaN device packaging;

- Aerospace & Defense: Radar systems, avionics cooling, hypersonic vehicle thermal shields;

- Optoelectronics: Laser diodes, LED arrays, fiber-optic transceivers;

- Consumer Tech: High-performance CPUs, gaming GPUs, and ultra-thin laptop heat spreaders.

Technical Superiority

- Precision Interface Bonding: Advanced vacuum hot-pressing ensures robust diamond-metal interfaces for minimal thermal resistance;

- Customizable Formulation: Fine-tune diamond size (50–200 μm), volume fraction, and matrix alloys (Cu, Al, Ag) for mission-specific requirements;

- Reliability: Stable performance under extreme conditions (–200°C to +500°C), withstanding thermal cycling and mechanical shock.

Why Our Diamond Composites?

- Performance Beyond Limits: Highest thermal conductivity among commercial composites;

- Weight-Saving Innovation: Replace conventional W/Cu or Mo/Cu with 30–50% lighter solutions;

- End-to-End Support: From material design to prototyping and mass production;

- Quality Assurance: ISO 9001-certified manufacturing with batch-to-batch consistency.

Elevate your thermal management strategy with diamond composites—where cutting-edge science meets engineering excellence.

📩 Contact us today for samples, datasheets, and custom solutions!

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074