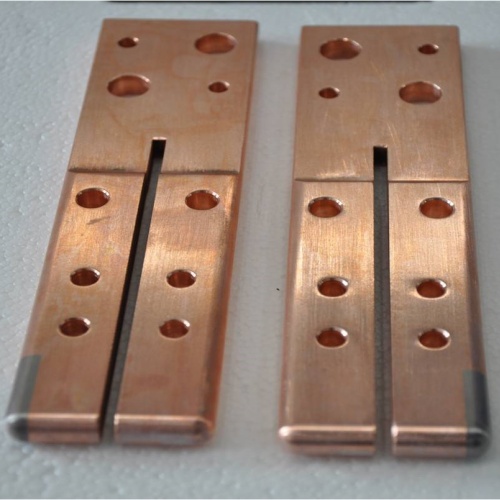

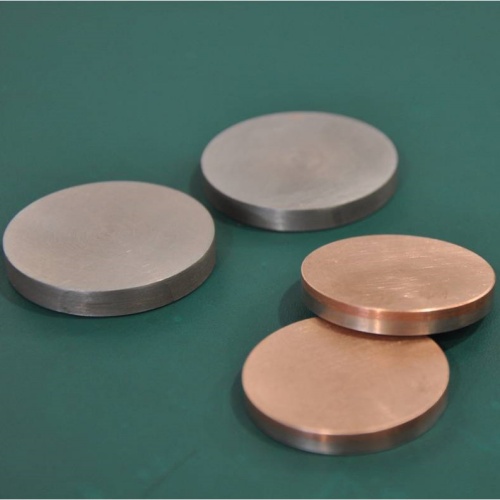

Customized Copper Tungsten Products

Applications of FOTMA customized tungsten copper alloy products:

Electronic heat dissipation: Customized heat sinks, heat dissipation bases, heat dissipation modules, etc. to ensure the normal operation of electronic equipment.

Welding electrodes: Customized resistance welding electrodes, spot welding electrodes, etc. to ensure welding quality and efficiency.

EDM: Customized EDM electrodes to meet the processing needs of high-precision molds and parts.

High-voltage switch: Customized high-voltage switch contacts, arc contacts, etc., to ensure the safe and stable operation of the power system.

Aerospace: Customized rocket nozzles, thermal management components, etc. to maintain stable performance in extreme environments.

Medical equipment: Customized X-ray tube anodes, etc. to ensure the efficient and stable operation of equipment.

In modern industry, where many applications demand on material properties, FOTMA offers customized tungsten-copper alloy product solutions based on its expertise and advanced technology in the field of copper tungsten alloys. Whether you need a specific shape, size, or have special requirements for material composition, FOTMA can meet your needs and provide you with customized products with high performance and reliability.

FOTMA has an experienced professional team and advanced production equipment, which can provide customers with comprehensive tungsten copper alloy customization services:

Comprehensive customized solutions: We are not just material suppliers, but also have a deeper understanding of customer needs, providing a complete set of customized solutions from material selection, design to production.

Material composition customization: FOTMA can flexibly adjust the ratio of tungsten and copper according to your application needs, optimize the material’s conductivity, thermal conductivity, high temperature resistance and other properties to achieve the best use effect.

Precision machining: We are equipped with high-precision CNC machines that can process various complex shapes of tungsten copper alloy parts, ensuring accurate product dimensions and smooth surfaces.

Electric Discharge Machining (EDM): With advanced EDM equipment, we are able to perform precise EDM to meet high-precision and high demand machining needs.

Diverse processing methods: In addition to machining and electrical discharge machining, FOTMA also offers various processing methods such as grinding and wire cutting to meet the needs of different customers.

Strict quality control: We conduct rigorous quality testing on every customized product to ensure that it meets the highest quality standards and customer requirements.

Fast prototyping and delivery: We are committed to responding quickly to customer needs, providing fast prototyping and reliable delivery services, and shortening your project cycle.

Applications of FOTMA customized tungsten copper alloy products:

Electronic heat dissipation: Customized heat sinks, heat dissipation bases, heat dissipation modules, etc. to ensure the normal operation of electronic equipment.

Welding electrodes: Customized resistance welding electrodes, spot welding electrodes, etc. to ensure welding quality and efficiency.

EDM: Customized EDM electrodes to meet the processing needs of high-precision molds and parts.

High-voltage switch: Customized high-voltage switch contacts, arc contacts, etc., to ensure the safe and stable operation of the power system.

Aerospace: Customized rocket nozzles, thermal management components, etc. to maintain stable performance in extreme environments.

Medical equipment: Customized X-ray tube anodes, etc. to ensure the efficient and stable operation of equipment.

Why Choose FOTMA’s customized copper tungsten alloy products:

Tailor-made: Customized material composition, shape and size according to your specific needs.

Excellent performance: Combining the excellent properties of tungsten and copper, it provides excellent electrical conductivity, thermal conductivity, high temperature resistance and other properties.

High Quality: Strict quality control ensures that products meet the highest standards.

Rapid Delivery: Rapid response to customer needs, providing fast sampling and delivery services.

Professional Support: Experienced team to provide professional technical support and consulting services.

When you choose FOTMA’s customized tungsten copper alloy products, you’ll get a high-quality, high-performance solution that perfectly meets your unique application needs. Whether you have special requirements for material composition, structural design, or machining accuracy, FOTMA can provide you with professional and reliable customized services. We are committed to be your reliable partner and work together with you to create a better future.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074