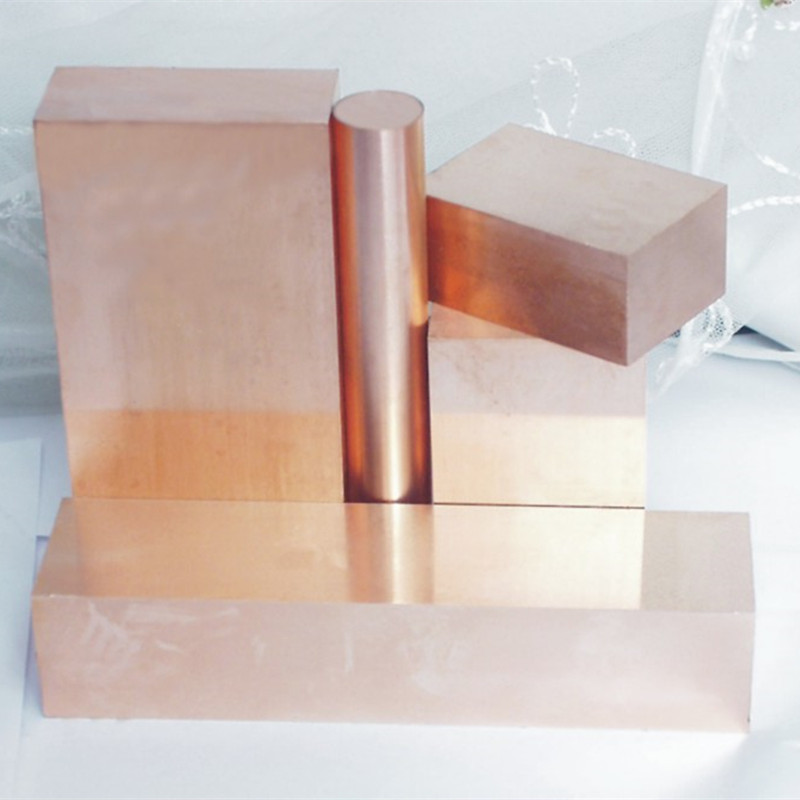

Copper Tungsten Plate / WCu Alloy Sheet

Tungsten copper (copper tungsten, CuW, or WCu) alloy is a pseudo-alloy of tungsten and copper. As copper and tungsten are not mutually soluble, the material is composed of distinct particles of one metal dispersed in a matrix of the other one. The micro-structure is therefore rather a metal matrix composite than a true alloy.

Tungsten copper (copper tungsten, CuW, or WCu) alloy is a pseudo-alloy of tungsten and copper. As copper and tungsten are not mutually soluble, the material is composed of distinct particles of one metal dispersed in a matrix of the other one. The microstructure is therefore rather a metal matrix composite than a true alloy.

Tungsten-copper alloy plate has a wide range of applications, mainly including:

Heat sinks and thermal base plates:

High power electronics, semiconductor packaging, LED lighting, aerospace, etc.

Application: As a heat sink or heat dissipation base plate, tungsten-copper alloy plate can quickly and effectively export heat out to ensure the stable operation of electronic equipment at a safe temperature and prolong its service life.

Advantage: High thermal conductivity and low coefficient of thermal expansion can effectively reduce thermal stress and improve equipment reliability.

Resistance welding electrode material:

Automotive manufacturing, electronics industry, metal processing, etc.

Application: Tungsten copper alloy plate can be used as a resistance welding electrode to withstand high current and high temperature impacts, ensuring welding quality.

Advantages: Good conductivity, thermal conductivity, wear resistance, and erosion resistance, which can extend the service life of electrodes and reduce failures.

Electro discharge machining (EDM) electrode:

Mold manufacturing, precision parts processing.

Application: As EDM electrode material, tungsten-copper alloy plate can withstand arc impact and ensure machining precision and efficiency.

Advantages: Characterized by good discharge performance and not easy to deform, it is suitable for fine machining.

High frequency induction heater components:

Metallurgical and heat treatment industries.

Application: Tungsten copper alloy plate can be used to make components for high-frequency induction heaters, which can withstand high-frequency currents and high-temperature impacts.

Advantages: High conductivity, high durability, excellent performance in the high-frequency field.

Thermal management components in the aerospace industry:

Space equipment such as rockets and satellites.

Application: As a component that is resistant to high temperatures, high strength, and high thermal conductivity, it ensures the performance of equipment in extreme environments.

Advantage: Able to maintain stable performance in extreme environments such as high temperature, high pressure, and high vacuum.

X-ray tube anode.

Medical, industrial inspection.

Application: As an X-ray tube anode, it can withstand high thermal load to ensure the stable operation of X-ray tube.

Advantage: Good thermal conductivity, can effectively dissipate heat and prolong the life of X-ray tube.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074