Copper Nickel Alloy

|

Parameter |

Typical Specifications |

| Common Grades |

CuNi10Fe1Mn (C70600), CuNi30Mn1Fe (C71500), Monel 400 (UNS N04400) |

|

Forms |

Plates (0.5–50 mm), Tubes (OD: 6–300 mm), Wires (φ0.1–20 mm), and Forgings |

| Chemical Composition (%) |

Ni: 10–30 / Cu: Balance / Fe: 1–2 / Mn: 0.5–1.5 (Note: Monel alloys contain ≥63% Ni) |

|

Mechanical Properties |

Tensile Strength: 300–600 MPa<br>Elongation: 25%–45% |

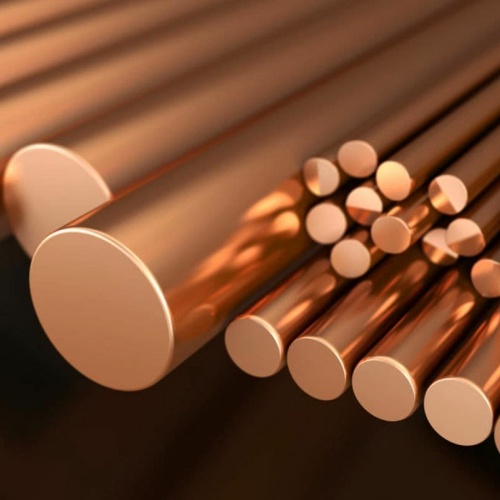

Copper Nickel Alloy (CuNi Alloy) Product Introduction–Multi-scenario solutions for corrosion resistance and high strength

Copper Nickel Alloy (Cu-Ni Alloy) is a functional material with copper as the matrix and nickel as the main alloying element, and the common models include Cu-Ni 90/10 (C70600), Cu-Ni 70/30 (C71500), and high-nickel corrosion-resistant alloys (e.g. Monel 400/ K500). These materials are known for their excellent seawater corrosion resistance, biofouling resistance, high thermal and electrical conductivity, and excellent process ability, making them ideal for use in offshore engineering, chemical equipment, power electronics, and other fields.

Advantage of Copper Nickel

Omni-directional corrosion resistance

Seawater corrosion resistance: In seawater, salt spray and chloride environment, copper-nickel alloy surface forms dense oxide film, corrosion rate is less than 0.025 mm/year, especially suitable for ship pipelines, desalination equipment.

Acid-resistant medium: stable resistance to dilute sulfuric acid, phosphoric acid, organic acids

Functional Versatility

Thermal/Electrical Conductivity: Conductivity of 14%–25% IACS (higher than stainless steel), suitable for high-current connectors and battery tabs.

Non-Magnetic: No hysteresis loss in strong magnetic fields, perfect for precision instruments and submarine cable sheaths.

Wear Resistance: Surface hardness can be enhanced via cold working, meeting the needs of wear-prone components like valves and pump bodies.

Strong mechanical properties

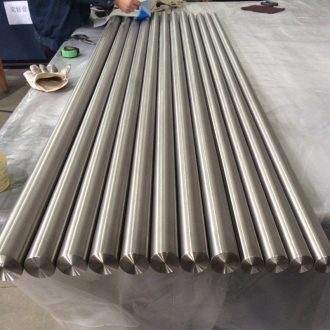

Excellent hot and cold processing performance: can be rolled, stretched, forged into plate, pipe, wire, hardness range 80~250 HV (annealed to hard state).

Good low-temperature toughness: maintains good ductility at -196°C, suitable for LNG storage tanks and low-temperature heat exchangers.

Product Type:

copper nickel sheet, copper nickel tube, copper nickel bar, copper nickel round bar, copper nickel alloy tubing

Product Forms & Specifications

| Parameter | Typical Specifications |

| Common Grades | CuNi10Fe1Mn (C70600), CuNi30Mn1Fe (C71500), Monel 400 (UNS N04400) |

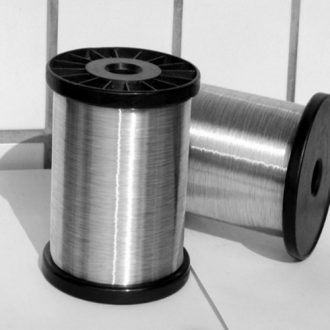

| Forms | Plates (0.5–50 mm), Tubes (OD: 6–300 mm), Wires (φ0.1–20 mm), and Forgings |

| Chemical Composition (%) | Ni: 10–30 / Cu: Balance / Fe: 1–2 / Mn: 0.5–1.5 (Note: Monel alloys contain ≥63% Ni) |

| Mechanical Properties | Tensile Strength: 300–600 MPa<br>Elongation: 25%–45% |

| Corrosion Resistance | Seawater Corrosion Rate: ≤0.03 mm/year (ASTM G52 test) |

| Electrical Conductivity | 14–25% IACS (varies with Ni content) |

| Operating Temperature | -200°C to +400°C (long-term service) |

Quality & Certifications

- International Standards: Compliant with ASTM B122/171, EN 12449, ISO 1634, and more.

- Testing Assurance: Includes chemical composition analysis (spectrometry), intergranular corrosion testing (ASTM G28), and hardness/tensile reports.

- Custom Services: Non-standard sizes, special heat treatments (annealing/solution), and surface treatments (passivation, tin plating).

Why Choose Copper Nickel Material?

- Low Lifecycle Costs: Corrosion resistance minimizes maintenance downtime and replacement frequency.

- Adaptability to Harsh Environments: Consistent performance in Arctic cold, tropical seas, acidic chemical plants, and high-humidity electrical fields.

- Sustainability: Over 90% recyclability, aligning with green manufacturing trends.

CONTACT US NOW TO GET LATEST COPPER NICKEL ALLOY PRICE!

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074