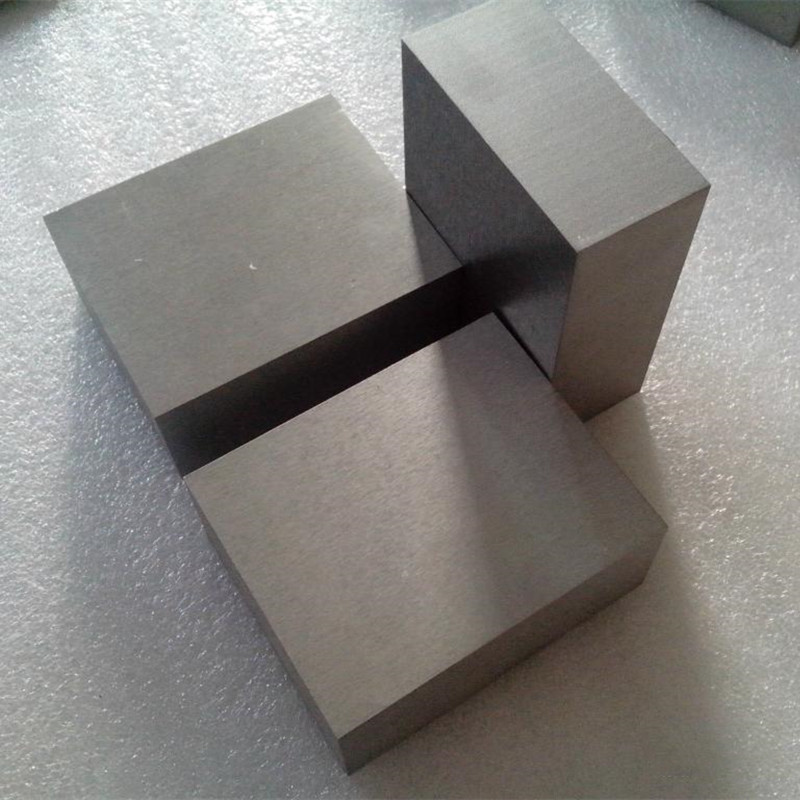

AgW Silver Tungsten Alloy

|

Grade |

Ag % |

WC % |

Density g/cm3 (≥) |

Conductivity IACS/% (≥) |

Hardness |

|

AgWC50 |

50±2 | Bal. | 12.20 | 29 |

85 |

|

AgWC40 |

60±2 | Bal. | 11.7 | 34 |

75 |

|

AgWC30 |

70±2 | Bal. | 11.2 | 36 |

57 |

Silver tungsten alloy (AgW Alloy) is a composite material that combines the excellent conductivity of silver with the high melting point and hardness characteristics of tungsten. Through a unique powder metallurgy process, these two metals are perfectly combined, giving silver tungsten alloy excellent electrical contact performance, wear resistance, and ablation resistance, making it play an irreplaceable role in many industrial fields.

Main Characteristics of Silver Tungsten Alloy:

Excellent conductivity: Silver is one of the metals with the best conductivity, and silver tungsten alloy inherits the good conductivity of silver, resulting in lower current loss.

High melting point and high hardness: Tungsten has an extremely high melting point (about 3422 ° C) and hardness, which makes silver tungsten alloy have excellent resistance to arc erosion and wear.

Good oxidation resistance: Appropriate alloy ratios can improve its oxidation resistance to a certain extent, enabling it to work stably even at higher temperatures.

High density: Silver tungsten alloy has a high density, which gives it a quality/volume advantage in certain applications.

Machinability: Although tungsten itself is difficult to process, the addition of silver gives silver tungsten alloys a certain degree of process ability, which can be formed through machining, electrical discharge machining, and other methods.

Customizability: The ratio of silver and tungsten can be adjusted according to different application requirements to achieve optimal performance.

Silver tungsten alloy has a wide range of applications, mainly including:

High voltage circuit breaker and contactor:

High-voltage switchgear, large power systems, substations, power grids, etc.

Uses: As the electric contact material of high-voltage circuit breaker and contactor, silver tungsten alloy can effectively resist arc ablation and fusion welding when opening and closing the current, ensuring the reliability of equipment operation.

Advantage: Able to withstand high current and high voltage impact, with long life and high reliability.

Electro discharge machining (EDM) electrode:

Mold manufacturing, precision parts processing, metal cutting, etc.

Usage: Silver tungsten alloy electrode can effectively resist the melting and ablation of the electrode in the process of EDM to ensure the machining precision and efficiency.

Advantage: With good discharge performance and wear resistance, it can realize fine processing and prolong the service life of electrode.

Welding Electrode:

Resistance welding, spot welding, seam welding, etc.

Usage: Silver tungsten alloy welding electrode can withstand high temperature and high pressure, maintain good contact to ensure welding quality and reliability.

Advantage: It is not easy to be deformed and melted during the welding process, and has a long service life.

Motor brush:

Large motors, DC motors, etc.

Usage: As the material of motor brush, silver tungsten alloy has good conductivity and wear resistance, which can ensure the reliable operation of motor.

Advantage: Reduce the wear of brushes, reduce the maintenance cost and improve the overall life of the motor.

Aerospace:

Rocket nozzles, satellite control systems, etc.

Usage: Provide good performance under high temperature, high pressure and high corrosive environments, such as arc contact points and conductive components.

Advantage: Maintains structural and performance reliability in harsh environments.

Medical Devices:

Uses: As a component of radiation therapy equipment, such as high strength shielding materials or electrodes.

Advantage: Good radiation barrier and biocompatibility.

Silver Tungsten Alloy Properties:

| Code No. | Chemical Composition % | Mechanical properties | ||||||

| Ag | Impurity≤ | W | Density (g/cm3 ) ≥ |

Hardness HB ≥ |

RES (μΩ·cm) ≤ |

Conductivity IACS/ % ≥ |

TRS/ Mpa ≥ |

|

| AgW(30) | 70±1.5 | 0.5 | Balance | 11.75 | 75 | 2.3 | 75 | |

| AgW(40) | 60±1.5 | 0.5 | Balance | 12.40 | 85 | 2.6 | 66 | |

| AgW(50) | 50±1.5 | 0.5 | Balance | 13.15 | 105 | 3.0 | 57 | |

| AgW(55) | 45±2.0 | 0.5 | Balance | 13.55 | 115 | 3.2 | 54 | |

| AgW(60) | 40±2.0 | 0.5 | Balance | 14.00 | 125 | 3.4 | 51 | |

| AgW(65) | 35±2.0 | 0.5 | Balance | 14.50 | 135 | 3.6 | 48 | |

| AgW(70) | 30±2.0 | 0.5 | Balance | 14.90 | 150 | 3.8 | 45 | 657 |

| AgW(75) | 25±2.0 | 0.5 | Balance | 15.40 | 165 | 4.2 | 41 | 686 |

| AgW(80) | 20±2.0 | 0.5 | Balance | 16.10 | 180 | 4.6 | 37 | 726 |

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074