Heating Elements

|

Parameter |

Molybdenum Disilicide (MoSi₂) | Silicon Carbide (SiC) |

| Max Operating Temperature | 1900°C (in air) |

1600°C (in air) |

|

Resistivity (Room Temp) |

0.25×10⁻⁶ Ω·m | 1.0–5.0×10⁻⁶ Ω·m |

| CTE | 8.1×10⁻⁶/°C |

4.5×10⁻⁶/°C |

|

Thermal Conductivity |

25 W/m·K |

120 W/m·K |

Molybdenum Disilicide (MoSi₂) and Silicon Carbide (SiC) Heating Elements: High-Efficiency Thermal Solutions for Extreme-Temperature Industries

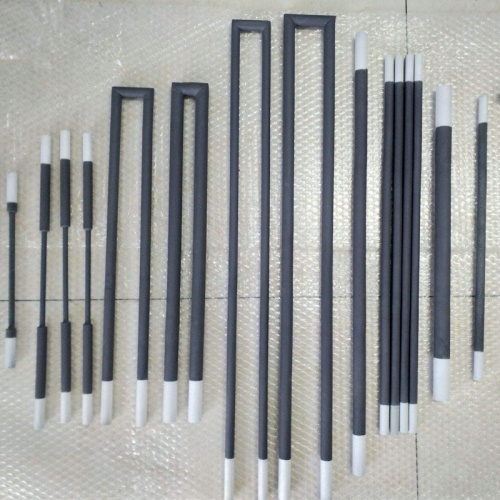

Molybdenum disilicide (MoSi₂) and silicon carbide (SiC) heating elements are core components in high-temperature industrial equipment, designed for extreme thermal environments. Widely used in ceramic sintering, semiconductor manufacturing, glass melting, and metal heat treatment, these elements leverage their unique material properties to deliver exceptional high-temperature stability, oxidation resistance, and energy efficiency, making them ideal replacements for traditional metal heaters.

Key Advantages Comparison

Molybdenum Disilicide (MoSi₂) Heating Elements

- Ultra-High Temperature Performance

-

- Operating Temperature: Up to 1900°C in oxidizing atmospheres, with short-term tolerance to 2100°C, ideal for ultra-high-temperature sintering furnaces and single-crystal growth systems.

- Self-Healing Oxide Layer: Forms a dense SiO₂ protective film at high temperatures to prevent oxidation, extending lifespan to 2–3 years (continuous use).

- Low Resistivity & High Emissivity

-

- Resistivity: 0.25×10⁻⁶ Ω·m (room temperature), increasing linearly with temperature for stable power output.

- Radiation Efficiency: >90%, ensuring uniform furnace temperature (±5°C).

- Lightweight & Easy Installation

-

- Density: 5.9–6.1 g/cm³, lighter than SiC, suitable for suspended or embedded setups.

Silicon Carbide (SiC) Heating Elements

- High Strength & Thermal Shock Resistance

-

- Operating Temperature: Long-term use at 1600°C (in air), short-term up to 1800°C, with excellent thermal shock resistance (ΔT >500°C/min).

- Mechanical Strength: Room-temperature flexural strength ≥300 MPa, maintaining rigidity under high loads.

- Corrosion Resistance

-

- Resists acidic/alkaline gas erosion, ideal for semiconductor CVD processes and aluminum melting furnaces.

- Cost Efficiency & Longevity

-

- 30–40% lower cost than MoSi₂, with an average lifespan of 3–5 years (intermittent use).

Technical Specifications Comparison

| Parameter | Molybdenum Disilicide (MoSi₂) | Silicon Carbide (SiC) |

| Max Operating Temperature | 1900°C (in air) | 1600°C (in air) |

| Resistivity (Room Temp) | 0.25×10⁻⁶ Ω·m | 1.0–5.0×10⁻⁶ Ω·m |

| CTE | 8.1×10⁻⁶/°C | 4.5×10⁻⁶/°C |

| Thermal Conductivity | 25 W/m·K | 120 W/m·K |

| Typical Shapes | U-shaped, rods, spirals | Straight rods, 3-phase stars, tubes |

| Startup Speed | Requires pre-oxidation (slow) | Fast startup (no pretreatment) |

| Compatible Atmospheres | Oxidizing, inert | Oxidizing, reducing, vacuum |

| Lifespan (Continuous Use) | 2–3 years | 3–5 years (intermittent) |

| Cost | High | Moderate |

Typical Applications

Molybdenum Disilicide (MoSi₂)

- High-Temperature Ceramic Sintering: Si₃N₄, SiC ceramics at 1700–1900°C.

- Optical Glass Melting: High-purity glass fusion (e.g., fiber preforms) in low-contamination environments.

- Single-Crystal Growth Furnaces: High-temperature pulling of sapphire (Al₂O₃) and silicon crystals.

Silicon Carbide (SiC)

- Semiconductor Diffusion Furnaces: Wafer doping and annealing (1200–1500°C).

- Metal Heat Treatment: Solution treatment and aging of titanium/aluminum alloys.

- Industrial Kilns: Refractory material firing and powder metallurgy sintering.

Selection Guidelines

- Choose MoSi₂ for:

-

- Ultra-high temperatures (>1600°C) in oxidizing atmospheres with continuous operation.

- Applications demanding extreme temperature uniformity (e.g., optical material processing).

- Choose SiC for:

- Medium-high temperatures (<1600°C) with frequent thermal cycling (intermittent use).

- Corrosive gas environments or cost-sensitive projects.

Customization Services

- Dimensional Design: Custom diameters (10–100 mm), lengths (200–3000 mm), and complex shapes (multi-zone heating).

- Surface Treatments:

- MoSi₂: Pre-oxidized coatings, Al₂O₃ reinforcement layers.

- SiC: SiC-Si composite coatings, anti-oxidation glazes.

- Accessories: Matched refractory supports, water-cooled clamps, smart temperature control modules.

- Certifications: Material composition analysis (ASTM), high-temperature resistivity testing, and ISO 2409 adhesion certification.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074