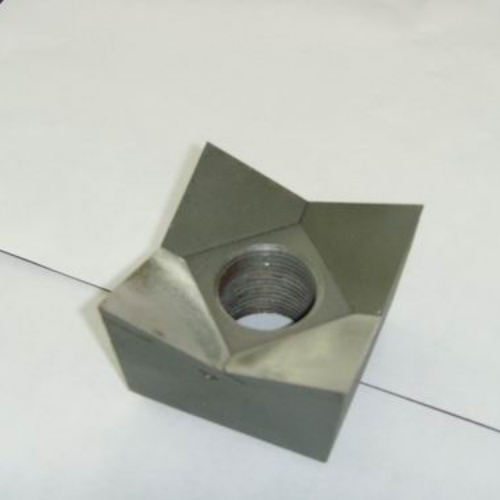

Cemented Carbide Cutting Tool

Material Grade for Tungsten Carbide Cutting Tools:

|

Grade |

Applications |

| C2 Uncoated |

High wear resistance and high strength; machining chilled cast iron and refractory steel, finishing of normal cast iron. |

|

C5 Uncoated |

Excellent in strength, impact resistance and resistance to thermal shock ; Rough turning, rough planing and semi planing of Carbon steel and alloy steel. |

|

ZK10UF |

Fine-grained alloy, good wear resistance and high strength. Semi-finishing and finishing of cast iron and nonferrous metals. It is the unique material for making of solid carbide tools for holing. |

| ZK30UF |

Fine grain grade. Excellent wear resistance, high in strength and impact resistance. Machining of cast irons, nonferrous metals and non-metallic materials. It is the unique material of solid carbide tools for holing. |

Tungsten Carbide Cutting Tools: Tailored Toughness for Maximum Uptime

Stop settling for off-the-shelf tools that underperform. FOTMA delivers custom carbide cutting tools, engineered for extreme wear resistance and peak efficiency in the toughest industries. Get the precise tool you need, exactly how you need it – boosting your productivity and slashing downtime.

Your Challenge, Our Custom Solution:

- Unleash Tailored Performance: We understand that standard tools often fall short. That’s why Fotma specializes in customization. From the carbide tip to the steel shank, every aspect of your cutting tool is designed to your exact specifications.

- Two-Part Precision – Total Flexibility: Our tools are built smart:

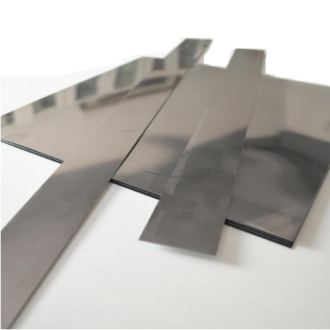

- Custom Carbide Tips: We formulate and shape the carbide tip for optimal hardness, wear resistance, and cutting geometry, perfectly matched to your material and application. Choose from a wide range of carbide grades and coatings.

- Custom Steel Shanks: Engineered for superior rigidity and vibration damping. We tailor the shank dimensions, mounting features, and steel grade to ensure perfect fit and performance in your machinery.

- Welded for Strength, Crafted for Longevity: Our carbide tips are expertly welded to steel shanks, creating a robust, integrated tool that withstands extreme forces and demanding conditions. Benefit from the wear resistance of carbide precisely where you need it, backed by the strength and adaptability of steel.

Industries We Power – Where Toughness Meets Efficiency:

- Crushing & Mining: Crushers, shredders, grinders – conquer abrasive materials with tools built for relentless impact and wear.

- Woodworking & Forestry: Chipper knives, planer blades, logging tools – achieve clean, efficient cuts in timber, even hardwoods and abrasive composites.

- Quarrying & Stone: Stone cutting, shaping, and profiling tools engineered for durability against hard stone and dust.

- Recycling: Shredding and granulating tools for abrasive materials like tires, plastics, and construction debris.

Customization Highlights:

- Carbide Grade Selection: Choose the ideal carbide grade for your material – from high-wear resistance to impact toughness.

- Tip Geometry & Edge Prep: Optimized cutting angles, chip breakers, and edge treatments for your specific application.

- Coating Options: Boost performance with advanced coatings like AlTiN, DLC, or specialized diamond coatings.

- Shank Dimensions & Features: Custom lengths, diameters, mounting holes, and coolant channels for perfect integration with your equipment.

- Material Selection (Shank): Choose steel grades based on required strength, stiffness, and corrosion resistance.

Benefits – Custom Built for Your Bottom Line:

- Maximize Uptime: Tools engineered for extended life in harsh conditions mean less frequent changes and more production.

- Boost Efficiency: Optimized cutting geometries and material-specific carbide grades increase cutting speeds and feed rates.

- Reduce Waste & Costs: Longer tool life and precise cutting minimize material waste and tooling expenses.

- Solve Complex Challenges: Custom tools tackle unique applications and materials that standard tools can’t handle.

Ready to Design Your Custom Carbide Insert Cutting Tools?

- Tell Us Your Needs: Contact our engineers and describe your application, materials, and equipment.

- Collaborative Design: We’ll work with you to design the perfect custom carbide cutting tool solution.

- Rapid Prototyping & Production: Experience fast turnaround on prototypes and production orders.

Get Started Today!

Fotma Custom Carbide Cutting Tools – Tougher Tools, Smarter Solutions.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074